The WHD-RQ400-BY digital thermostat is an intelligent control device designed specifically...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

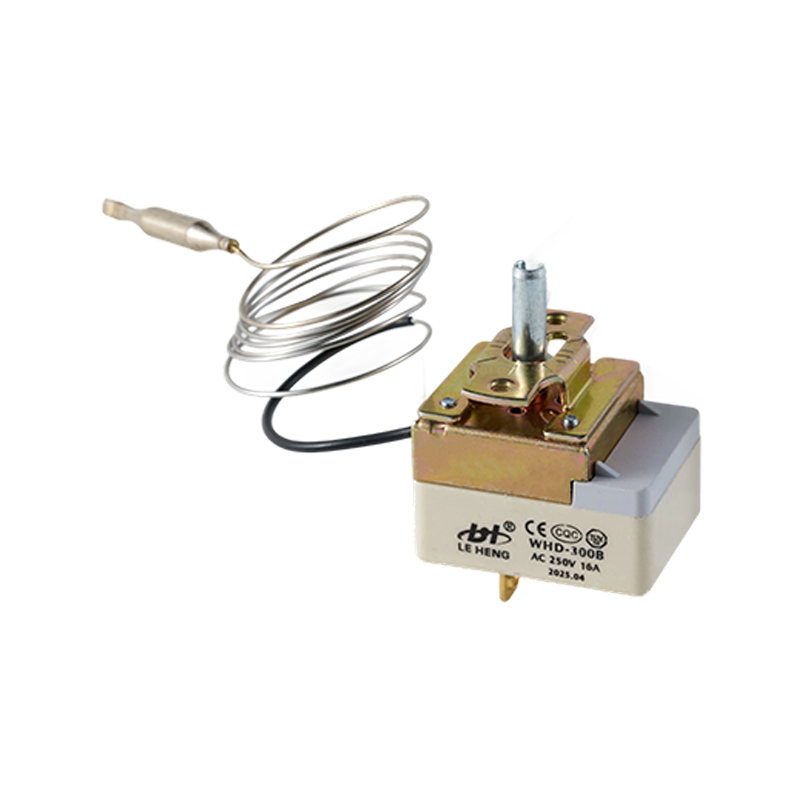

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

Thermoreat technology has undergone significant evolution as industries shift from purely mechanical designs toward more intelligent and electronically integrated solutions. While traditional thermoreats remain widely used for basic heating or cooling control, the demand for higher precision, programmability, and compact design has driven the development of PCB Thermoreats, Digital Thermoreats, and Temperature Digital Thermoreats. These products enable advanced temperature management across consumer electronics, industrial machinery, HVAC systems, and specialized equipment where accuracy and control stability are primary considerations.

Overview of Electronic Thermoreat Technology

Electronic thermoreats represent a shift from mechanical or capillary sensing to integrated circuits capable of processing temperature data with higher precision. Their benefits include:

- Improved accuracy and stability

- Programmable or preset temperature control

- Compact design suitable for PCB integration

- Flexible output methods including relays, MOSFETs, or signal outputs

- Compatibility with a wide range of temperature sensors

The development of printed circuit board (PCB) and digital thermoreat technologies supports both basic and advanced thermal-management needs in modern equipment.

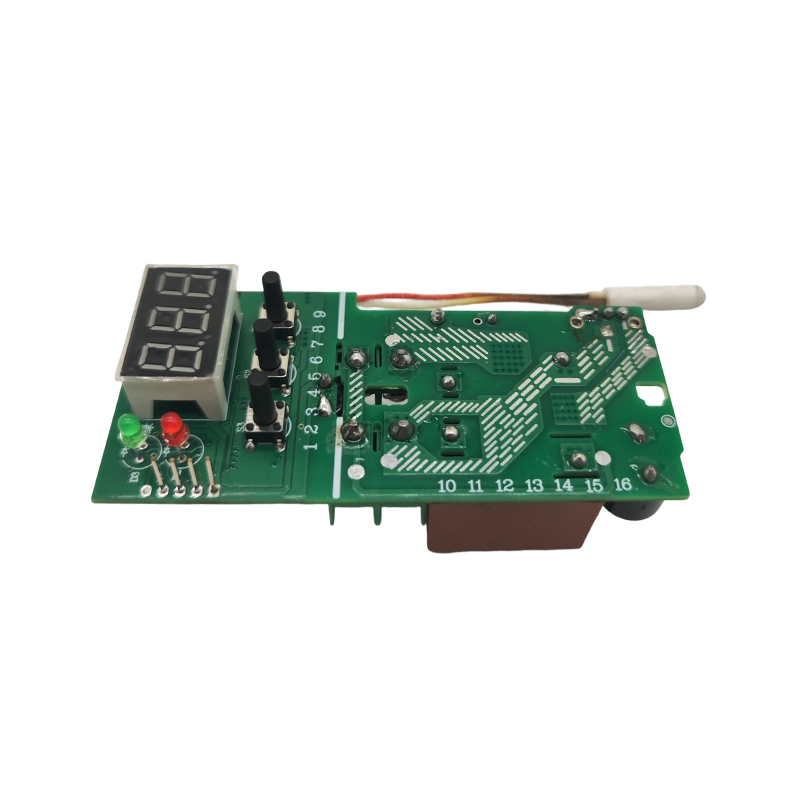

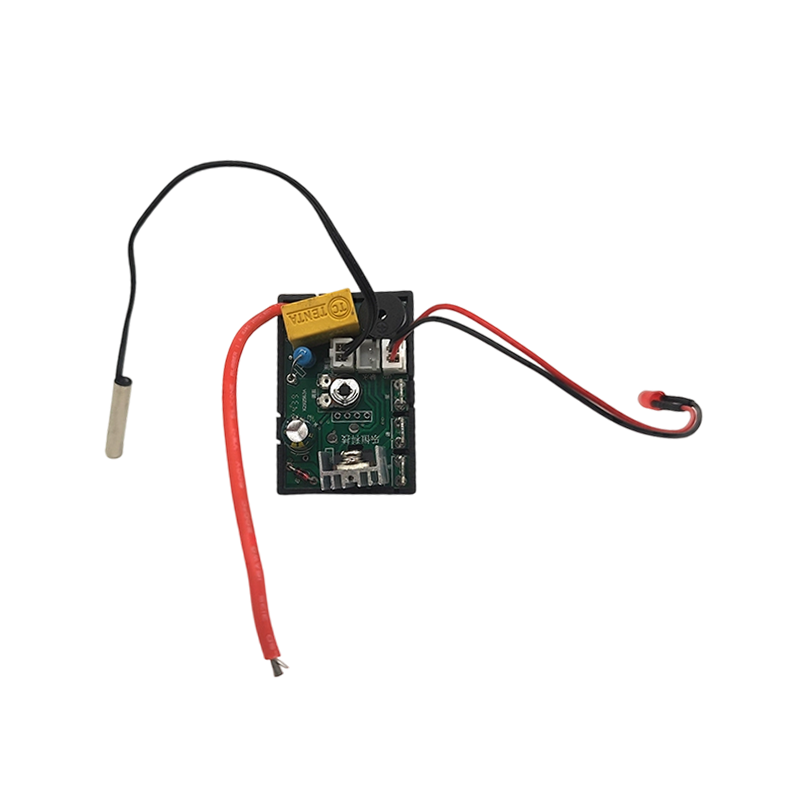

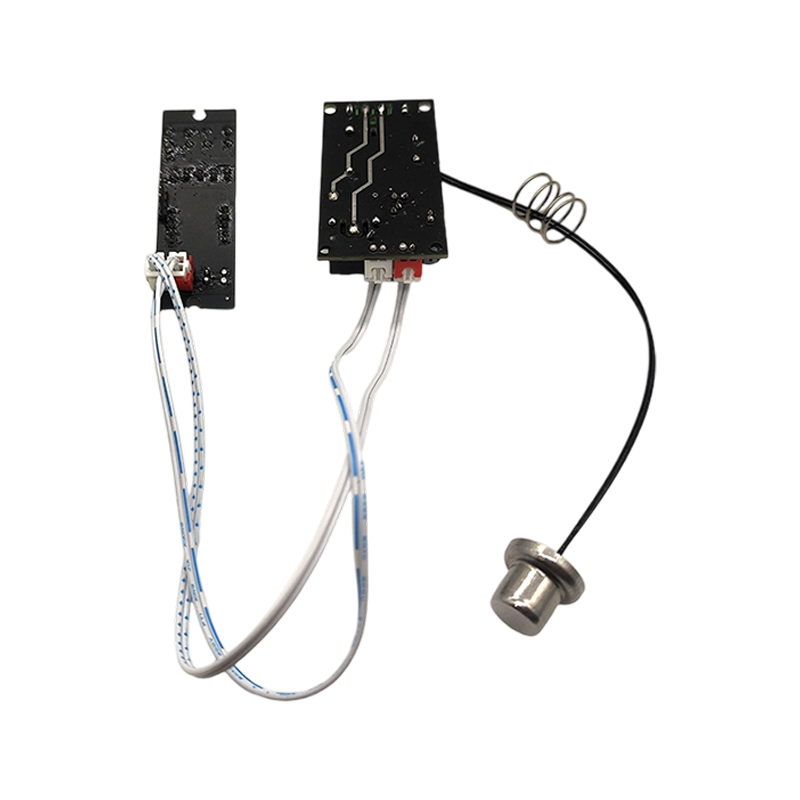

PCB Thermoreat

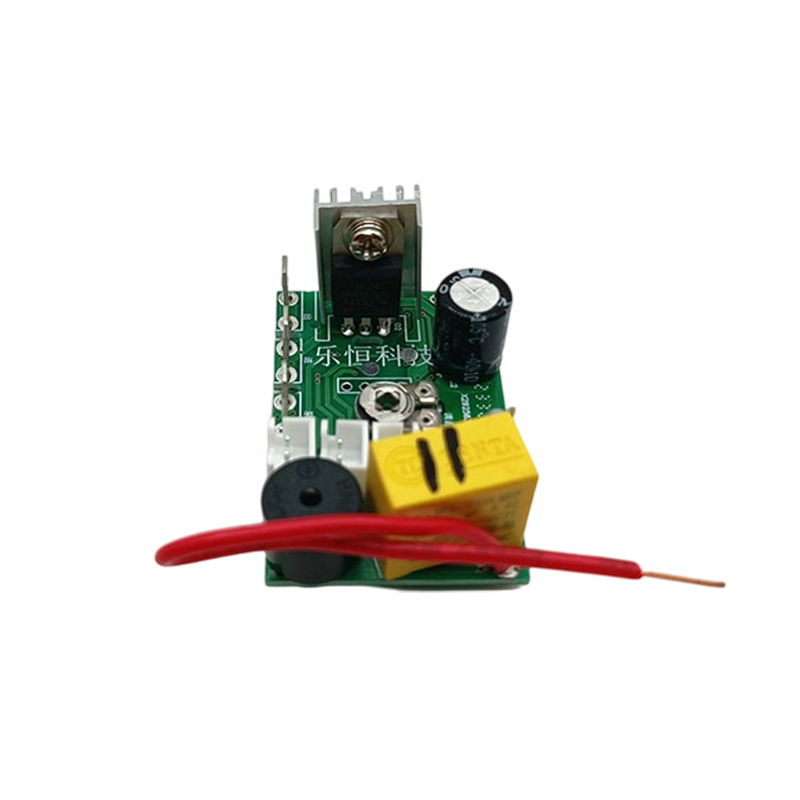

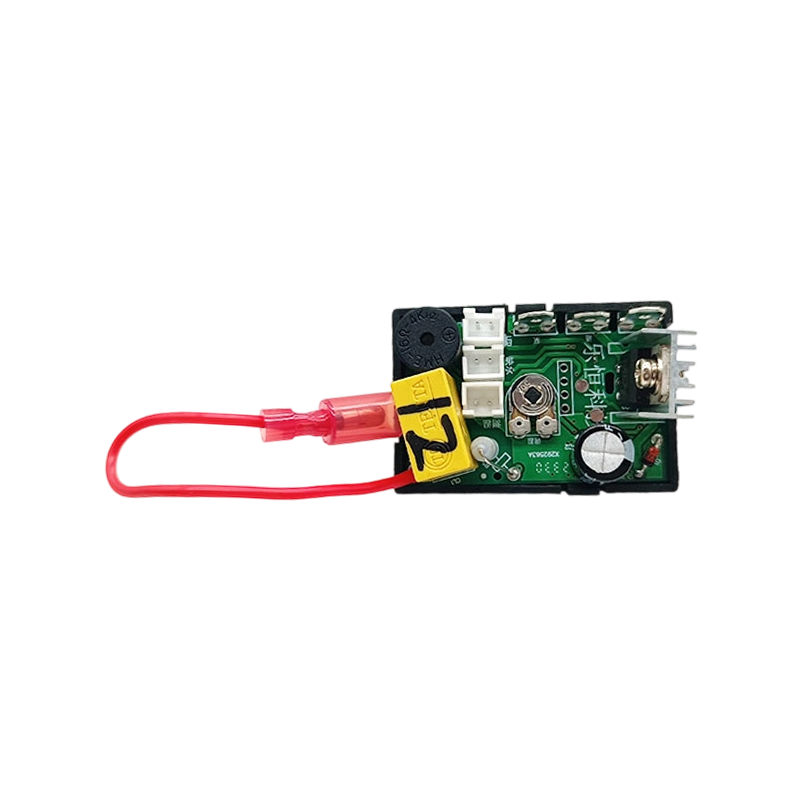

A PCB Thermoreat is an electronic thermoreat built directly onto a printed circuit board. It typically integrates a temperature sensor, electronic components, and switching elements to achieve accurate temperature control within compact equipment.

Structural Features

A standard PCB Thermoreat includes:

- Temperature sensor (NTC thermistor, digital sensor, or thermistor-based circuit)

- Microcontroller or electronic logic for processing temperature signals

- Switching output element (relay, triac, or transistor)

- PCB-mounted connectors or solder pads for equipment integration

- Voltage regulation circuits for stable operation

Because the entire control system is integrated onto a board, PCB Thermoreats are highly adaptable for custom equipment.

Functional Characteristics

- Provides consistent temperature measurement and control

- Can output switching signals to activate heaters, coolers, or fans

- Compact structure allows installation inside smaller devices

- Can be programmed or factory preset depending on requirements

Typical Applications

PCB Thermoreats are widely used in applications where space is limited and accurate electronic temperature regulation is required:

- Household and commercial appliances

- Consumer electronics thermal protection

- Industrial control modules

- Compact heating elements

- Environmental monitoring devices

- Battery management and charging systems

Their balance of size, reliability, and control accuracy makes them suitable for integrated system designs.

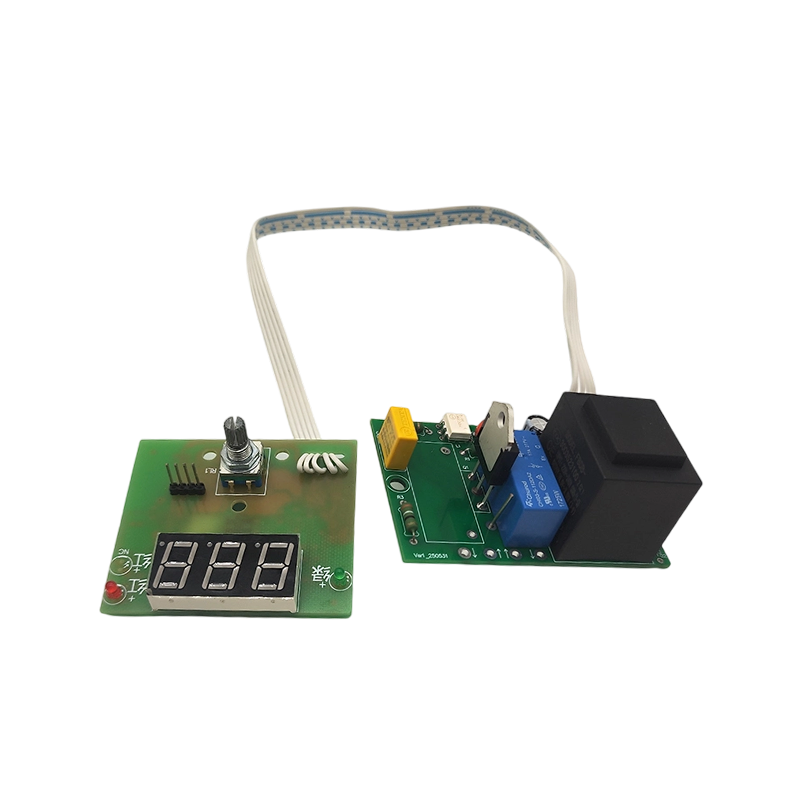

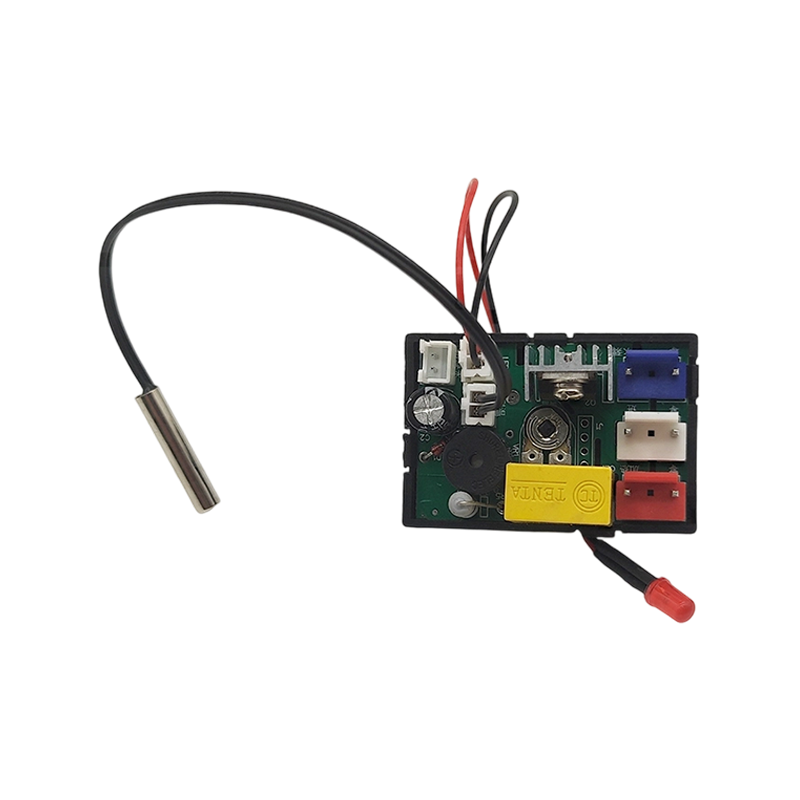

Digital Thermoreat

A Digital Thermoreat is an electronic thermoreat that uses a digital display and microprocessor to control temperature settings. It allows users to set precise temperature points and may include additional programmable features.

Key Components

A Digital Thermoreat typically includes:

- Digital display (LED or LCD)

- Microcontroller that calculates and responds to thermal changes

- Temperature sensor (NTC, RTD, or semiconductor-based)

- User interface such as buttons or touch controls

- Relay or electronic switching output

Functional Advantages

Digital Thermoreats provide benefits such as:

- Higher accuracy compared to mechanical thermoreats

- Easy-to-read temperature data

- User-programmable temperature settings

- Additional features such as timers or mode selection

- Greater consistency over wide temperature ranges

Due to their digital nature, these thermoreats support a variety of user requirements in both consumer and industrial environments.

Application Areas

Digital Thermoreats are commonly used in environments requiring stable, visible, and user-adjustable temperature control:

- HVAC equipment

- Heating appliances

- Laboratory and environmental chambers

- Agricultural systems

- Water heating devices

- Commercial food equipment

Their user-friendly interface makes them suitable for equipment requiring frequent temperature adjustments.

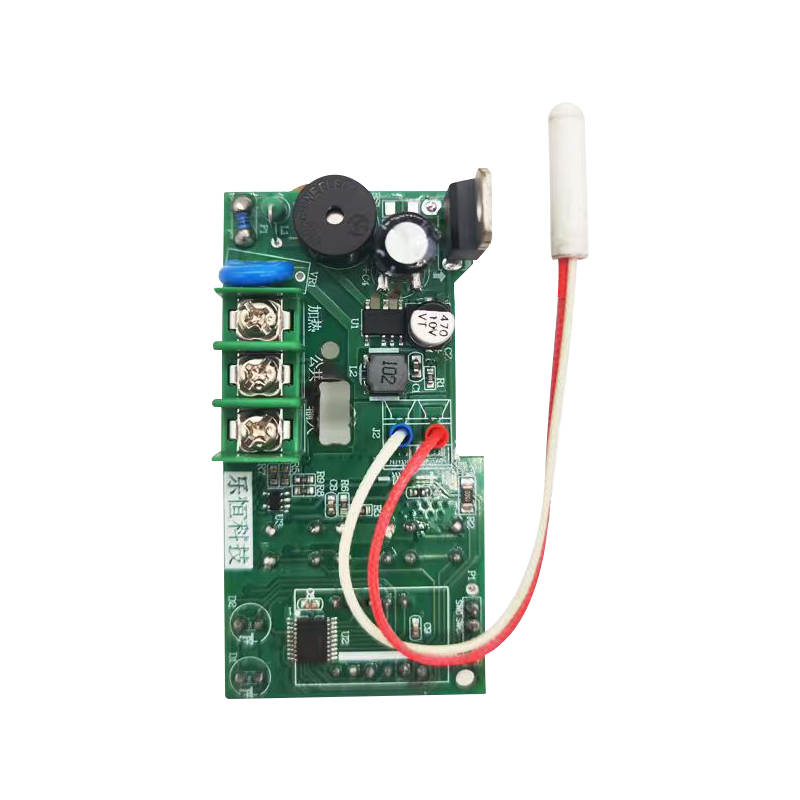

Temperature Digital Thermoreat

A Temperature Digital Thermoreat is a more advanced form of digital thermoreat designed specifically for precise thermal management. It frequently incorporates enhanced processing capabilities, multiple sensor options, and multi-stage control outputs.

Defining Characteristics

Compared with standard Digital Thermoreats, Temperature Digital Thermoreats often include:

- Higher-accuracy sensing components

- Multiple sensor input support

- Intelligent control algorithms such as proportional or time-based switching

- Configurable safety limits or alarms

- Multi-stage heating/cooling outputs

These features make them suitable for complex operational environments.

Advantages in Thermal Systems

- Enhanced accuracy

- Ability to maintain narrow temperature bands

- Programmable safety features

- Compatibility with multiple heating or cooling components

- Options for remote monitoring or data communication in some configurations

Usage Scenarios

Temperature Digital Thermoreats are widely used in environments requiring stable and precise temperature management:

- Laboratory equipment

- Incubation systems

- Industrial processing machinery

- Climate-controlled storage units

- Automation systems

- High-precision heating modules

Their advanced performance makes them a reliable choice for applications requiring precision beyond standard consumer-level thermoreat solutions.

Technical Comparison of PCB and Digital Thermoreat Categories

Below is a concise comparison highlighting key differences:

| Category | Structure | Adjustability | Sensor Type | Typical Applications |

| PCB Thermoreat | Board-mounted components | May be preset or programmable | NTC / RTD / semiconductor | Compact devices, electronics |

| Digital Thermoreat | Display + microprocessor | Fully user adjustable | NTC / RTD | HVAC, appliances |

| Temperature Digital Thermoreat | Advanced digital controller | Programmable with safety functions | Multiple sensor compatibility | Industrial, laboratory, precision systems |

This comparison demonstrates that each category fulfills a distinct role, from integrated control to advanced temperature regulation.

Working Principles of PCB/Digital Thermoreats

Despite functional differences, these devices follow similar thermal-control principles.

Temperature Sensing

Sensors detect temperature and change an electrical property (resistance, voltage, or digital signal). The controller interprets this data.

Processing Logic

Electronic logic or microprocessors evaluate:

- Current temperature

- Preset temperature

- Safety limits

- Timing parameters

Based on calculations, the thermoreat determines appropriate switching actions.

Switching Output

Electronic thermoreats can use:

- Relays for higher loads

- Transistors or MOSFETs for compact switching

- Signal outputs for integration with other systems

These outputs activate heaters, cooling fans, compressors, or alarms.

Industrial Trends Affecting Digital and PCB Thermoreat Development

Miniaturization and Integration

As devices become smaller, the demand for compact PCB thermoreats with multifunction capability increases.

Digitalization and Smart Control

Users expect precise control, visibility, and interface convenience, driving adoption of digital thermoreats.

Precision and Stability Requirements

Industrial and laboratory environments require tight temperature tolerances, boosting use of temperature digital thermoreats.

Sensor Technology Advancements

Modern sensors offer:

- Better accuracy

- Faster response

- Higher stability

These improvements enhance the performance of digital thermal controllers.

Selection Considerations for PCB and Digital Thermoreats

When selecting thermoreats within these categories, it is important to evaluate:

Temperature Range Requirements

Choose thermoreats with sensing and switching ranges appropriate to the equipment.

Power and Load Ratings

Match output switching capacity with heater or cooler specifications.

User Interface Needs

PCB thermoreats use internal presets or electronic logic.

Digital thermoreats provide user-friendly external controls.

Accuracy and Stability Levels

Precision needs vary by application; laboratory environments require higher accuracy than general consumer appliances.

Safety Features

- Some digital thermoreats include:

- Over-temperature alarms

- Lockout functions

- Data storage

Sensor Compatibility

Determine which sensor types are suitable for system layout and precision needs.

PCB and digital thermoreats represent important categories in modern temperature-control technology.

PCB Thermoreats offer compact, integrated control for electronics and small devices.

Digital Thermoreats support visible, user-adjustable temperature settings for HVAC systems, appliances, and commercial equipment.

Temperature Digital Thermoreats provide enhanced precision, programmability, and safety features for industrial and laboratory applications.

English

English Türk

Türk