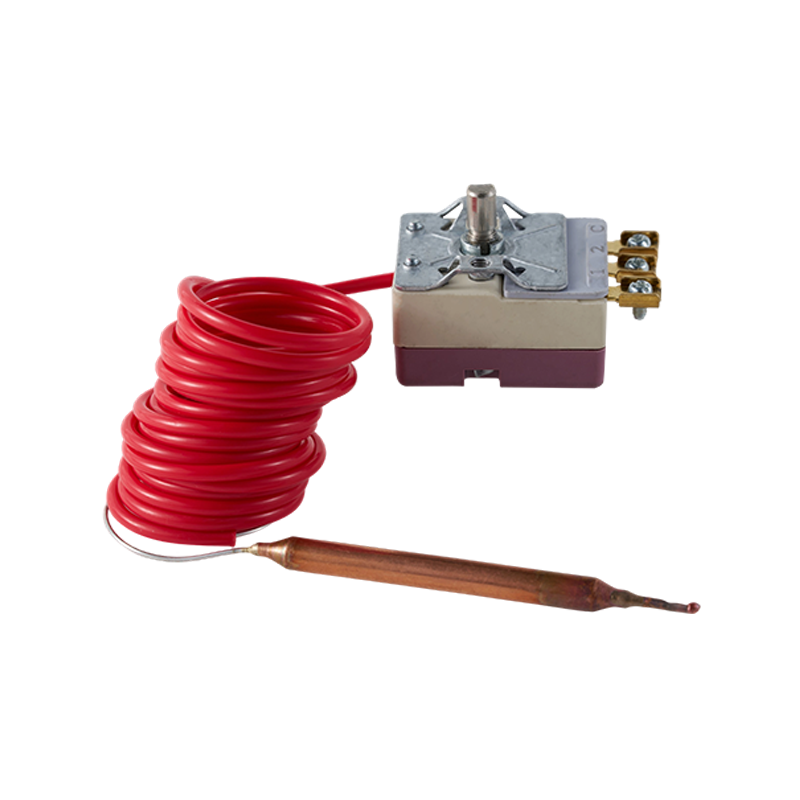

WHD-E copper adjustable copper capillary thermostat is a mechanical temperature regulating...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

Heating thermoreats are central components in temperature-regulation systems used in residential, commercial, and industrial environments. Their primary role is to sense temperature changes and control heating mechanisms to maintain stable thermal conditions. Among the various thermoreat types used in heating systems, capillary-based thermoreats hold an important place due to their flexible design, reliable performance, and adaptability across various equipment categories.

Introduction to Heating Thermoreat Technology

Heating thermoreats work by detecting environmental or surface temperature and activating or interrupting heating circuits when the temperature reaches a preset threshold. They can be divided into several categories based on sensing technology, switching structure, adjustability, and application type.

Common heating thermoreat categories include:

- Capillary Thermoreats

- Bimetallic Thermoreats

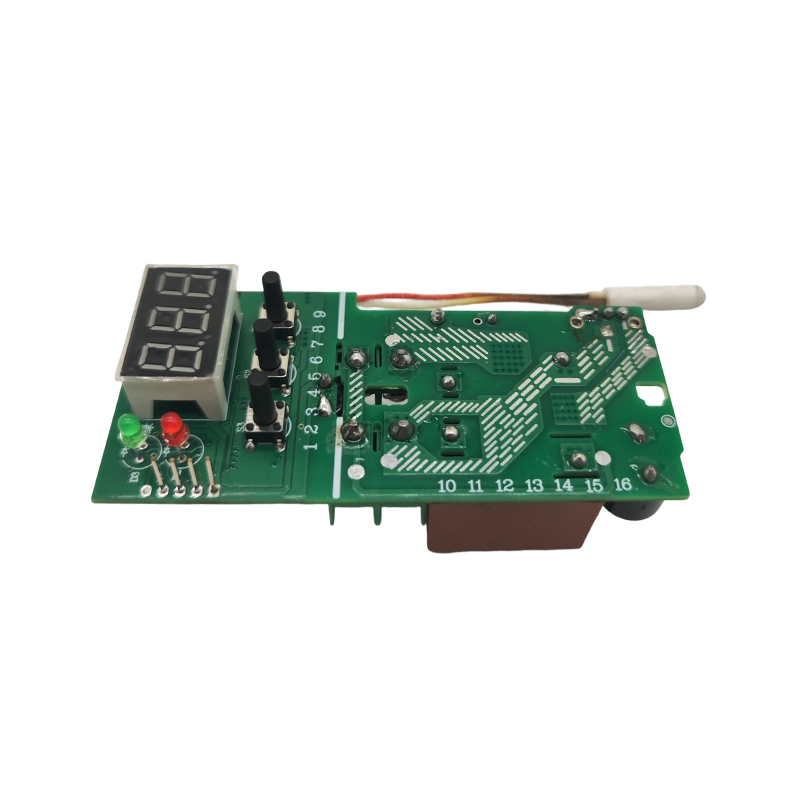

- Electronic Thermoreat Controllers

- Thermal Cutoff Safety Devices

- Programmable Digital Temperature Controllers

- Within these categories, capillary thermoreats provide an effective solution for many heating applications due to their mechanical reliability, broad temperature range capability, and ease of integration.

Capillary-Based Heating Thermoreat Categories

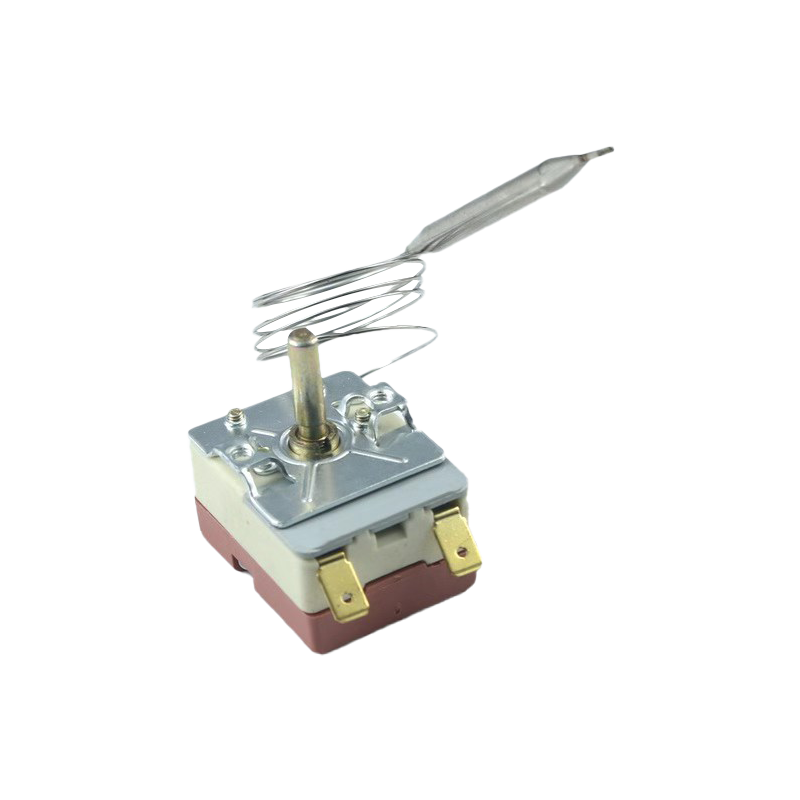

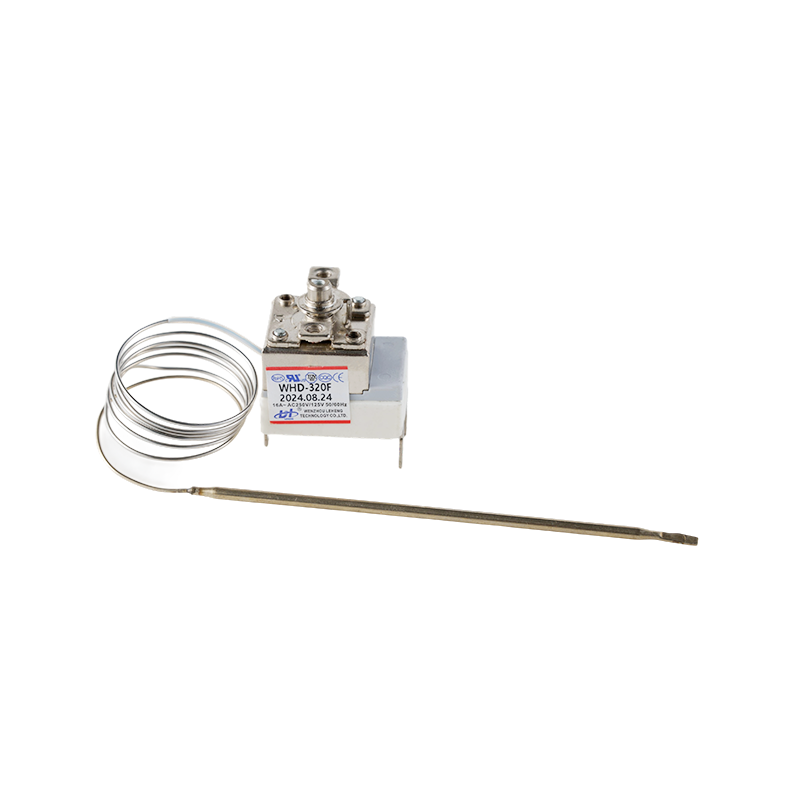

Capillary Adjustable Thermoreat

A Capillary Adjustable Thermoreat is a mechanical thermoreat that allows users to manually set the desired operating temperature. These devices use a capillary tube filled with temperature-responsive fluid that expands or contracts as temperature changes. The fluid movement activates an internal switch, turning heating elements on or off.

Key Characteristics

| Feature Category | Description |

| Adjustability | User-defined temperature setpoint via a dial or knob |

| Sensing Mechanism | Fluid expansion in capillary system |

| Switching Type | Mechanical on/off switching |

| Application | Heating appliances requiring adjustable settings |

Common Applications

- Room heaters

- Water heating devices

- Food warming equipment

- Industrial temperature-regulated chambers

Because the setpoint is adjustable, it is suitable for applications where temperature levels need periodic manual adjustment.

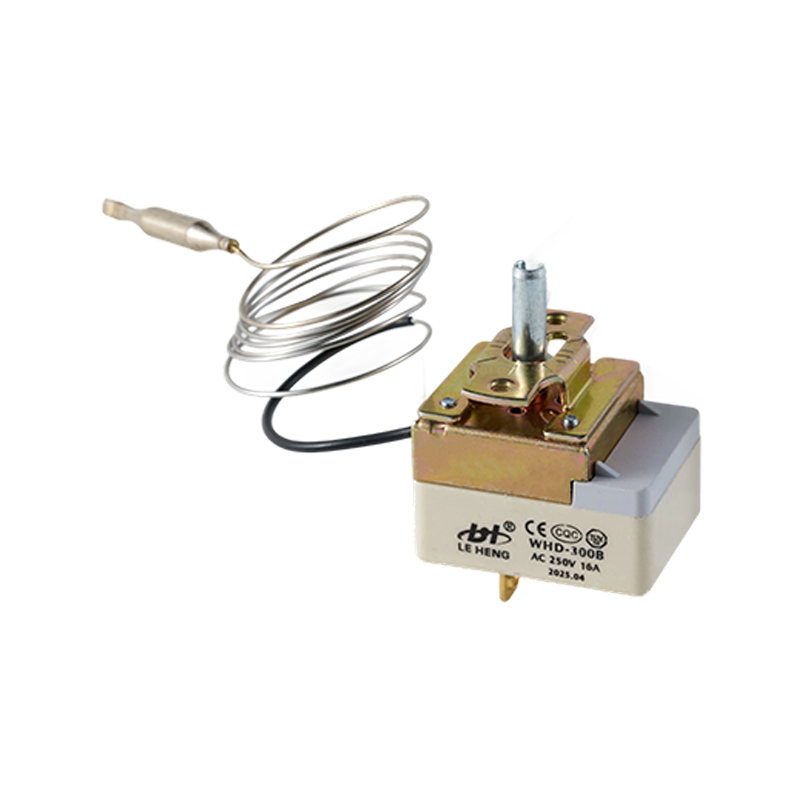

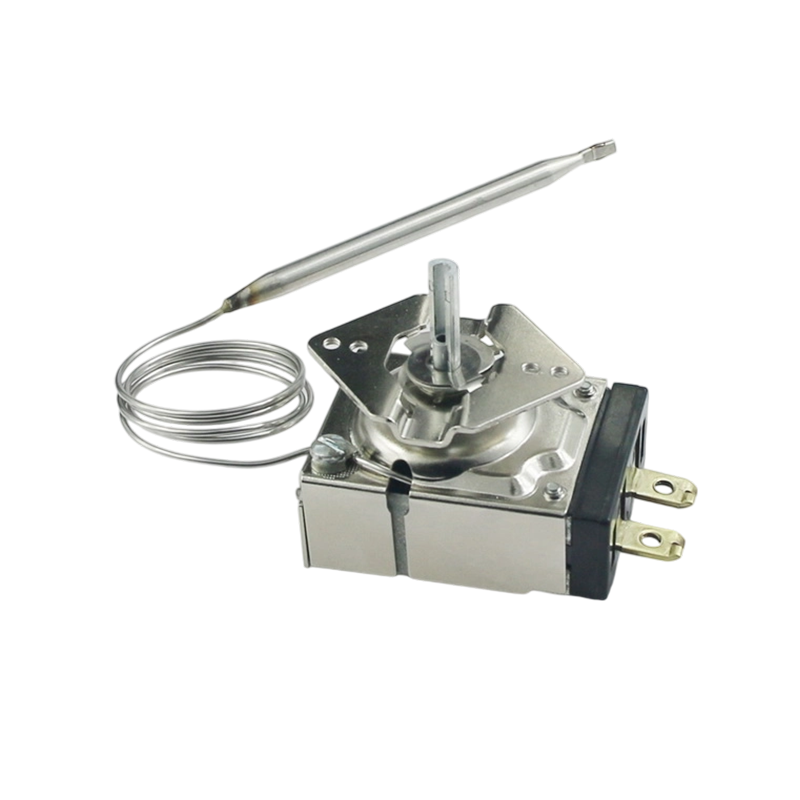

Capillary Thermoreat Temperature Controller

A Capillary Thermoreat Temperature Controller combines the mechanical sensing of a capillary system with controller-like functionality. These devices maintain stable heating conditions by monitoring temperature changes and cycling heating systems more precisely than basic thermoreats.

They are often used in systems requiring continuous thermal regulation rather than simple switching.

Key Characteristics

| Feature Category | Description |

| Control Method | Mechanical sensing combined with fine switching logic |

| Stability | Designed to maintain consistent temperature levels |

| Temperature Range | Medium to wide depending on capillary design |

| Integration | Suitable for panel-mounted or system-integrated use |

Typical Uses

- Boilers

- Electric water heating units

- Heat pumps

- Industrial circulating heating systems

- Food processing or storage heating equipment

This type is ideal for applications where temperature must remain stable within a controlled range, not simply below an upper limit.

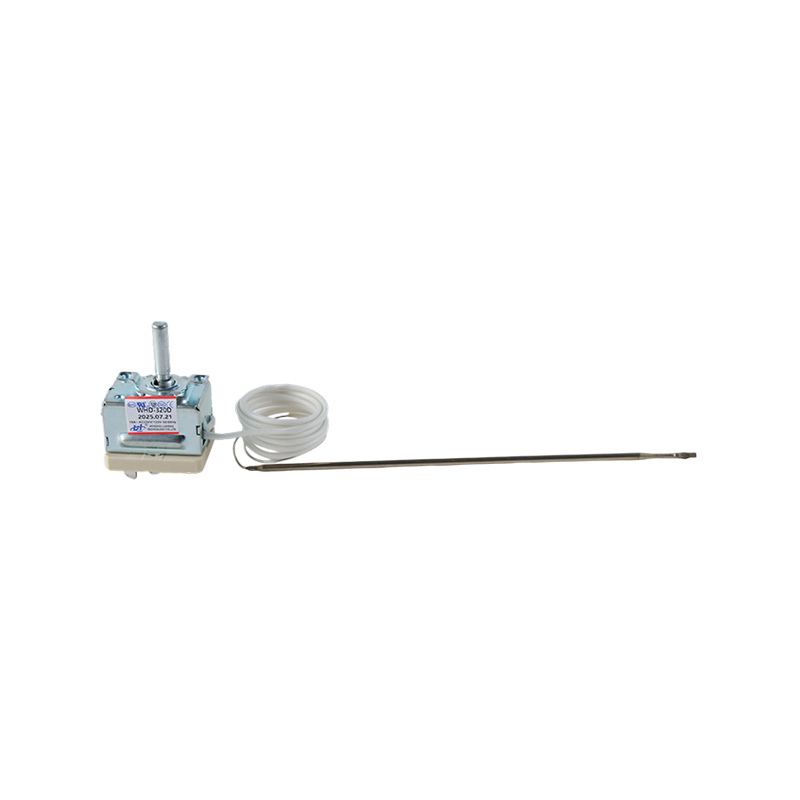

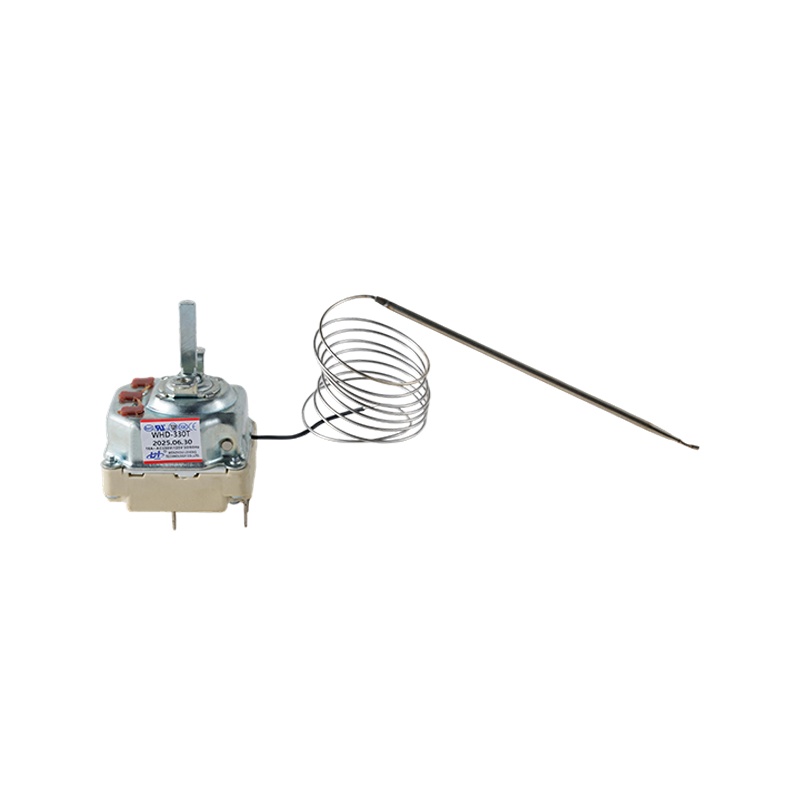

Capillary Tube Thermoreat

A Capillary Tube Thermoreat is structured around a long, flexible capillary sensing tube, enabling placement of the sensing bulb at distant or hard-to-reach points relative to the control unit. This flexibility makes it compatible with equipment where heat sources or measurement points are separated from the mechanical switching housing.

Key Characteristics

| Feature Category | Description |

| Sensing Tube Length | Allows remote sensing up to several meters |

| Installation Flexibility | Bulb placement independent of control unit |

| Switching Mechanism | Mechanical micro-switch activated by pressure variation |

| Durability | Designed for steady heating cycles |

Typical Applications

- Ovens

- Industrial heating plates

- Air heaters

- Commercial cooking equipment

- Heat exchangers

Its extended tube design supports versatile installation positions, making it widely used across heating systems with specific layout constraints.

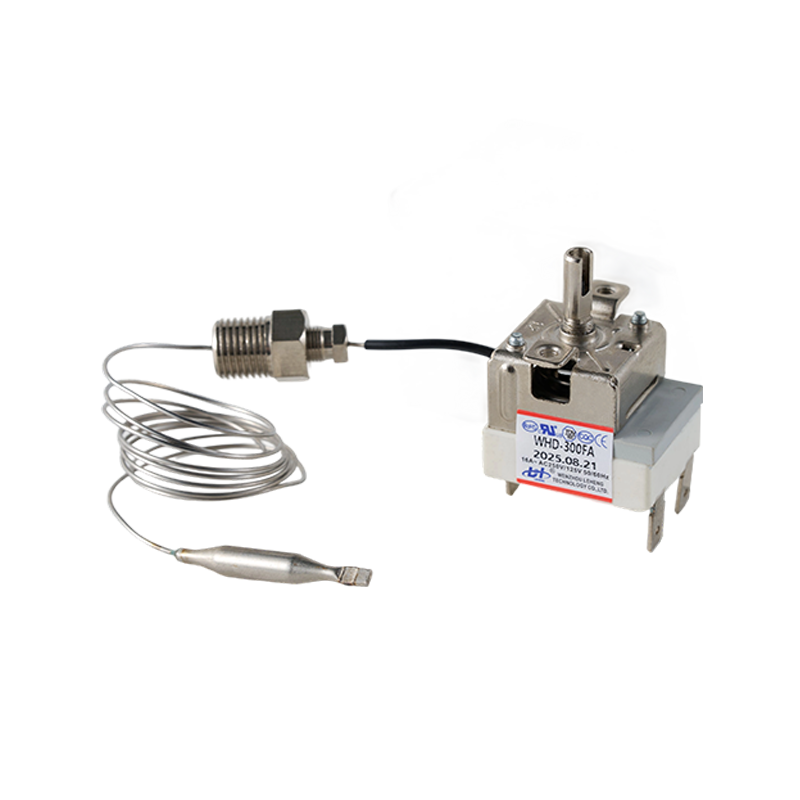

Temperature Control Switch Capillary Thermoreat

A Temperature Control Switch Capillary Thermoreat is primarily a safety or limit-control device used to interrupt heating when temperature exceeds a fixed threshold. Unlike adjustable capillary thermoreats, this type often features either:

- Fixed setpoint

- Factory-calibrated range

- Manual-reset protection in some models

It acts as a protective switch rather than a full temperature-regulation controller.

Key Characteristics

| Feature Category | Description |

| Control Function | Safety cutoff or limit-control |

| Setpoint | Fixed, factory-defined |

| Reset Mechanism | Auto or manual depending on model |

| Use Case | Over-temperature protection |

Common Applications

- Electric heating elements

- Industrial machinery protection

- Water heating systems

- HVAC safety features

- Heat-sensitive processing equipment

These devices are essential in systems where overheating could cause equipment malfunction or damaging thermal conditions.

Working Principle of Capillary Heating Thermoreats

All capillary-based thermoreats operate using the fluid expansion principle. Their internal structure typically includes:

- Sensing Bulb: Placed at the measurement point; filled with a temperature-sensitive fluid

- Capillary Tube: Transmits fluid pressure changes to the switch mechanism

- Bellows or Diaphragm: Converts pressure changes into mechanical movement

- Switch Mechanism: Activates heating system on/off

Working Process

- Temperature rises at the sensing bulb.

- Fluid expands and pressure increases within the capillary tube.

- Pressure activates bellows, causing switch movement.

- Switch opens or closes the circuit depending on the temperature setpoint.

- When the temperature drops, the fluid contracts, reversing the switch state.

This mechanical-based method ensures stable performance without dependence on external power or digital components.

Comparison of Capillary Heating Thermoreat Types

Below is a comparison summarizing the distinctions among the capillary thermoreat categories discussed:

Comparison Table

| Category | Adjustability | Primary Function | Sensing Flexibility | Common Applications |

| Capillary Adjustable Thermoreat | Manual adjustable | User-defined temperature control | Moderate | Heaters, warming equipment |

| Capillary Thermoreat Temperature Controller | Adjustable and stable control | Continuous thermal regulation | Moderate | Boilers, pumps, industrial systems |

| Capillary Tube Thermoreat | May be adjustable or preset | Heating control with remote sensing | High | Ovens, heating plates, commercial heaters |

| Temperature Control Switch Capillary Thermoreat | Usually fixed | Over-temperature safety protection | Moderate | Heat protection systems, HVAC safety |

Industry Applications and Integration Trends

Heating thermoreats are used across a wide range of industries due to their stability, mechanical reliability, and broad temperature tolerance.

Industrial Heating Equipment

Capillary-based thermoreats excel in:

- Industrial ovens

- Heating plates

- Plastic processing machines

- Textile equipment

Their mechanical responsiveness provides consistent thermal regulation.

Commercial Food and Beverage Equipment

They support heating functions in:

- Grills

- Warmers

- Steam tables

- Proofing cabinets

Temperature stability is essential for food safety and process consistency.

Residential and Commercial Heating

Applications include:

- Water heating units

- Electric heaters

- Radiant heating systems

Capillary thermoreats offer a simple and durable solution for common heating devices.

Key Factors in Selecting Heating Thermoreats

Professionals selecting heating thermoreats should evaluate several factors:

Temperature Range Requirements

Ensure the thermoreat's operational range matches the system’s expected temperature conditions.

Adjustability Needs

- Adjustable thermoreats for multi-purpose equipment

- Fixed for safety or standardized systems

Environmental Conditions

Consider:

- Humidity

- Vibration

- Mounting position

- Ambient temperature around control housing

Capillary Tube Length and Placement

Distance between sensing point and control unit determines required capillary length.

Switching Capacity

Match voltage and current rating to the heating element being controlled.

Reset Mechanism

Safety-critical systems may require manual-reset versions to ensure safe restart procedures.

Heating thermoreats are essential components across a broad range of systems requiring temperature regulation or over-temperature protection. Among the classifications, capillary-based designs—including Capillary Adjustable Thermoreats, Capillary Thermoreat Temperature Controllers, Capillary Tube Thermoreats, and Temperature Control Switch Capillary Thermoreats—provide flexible sensing solutions, stable performance, and broad applicability.

English

English Türk

Türk