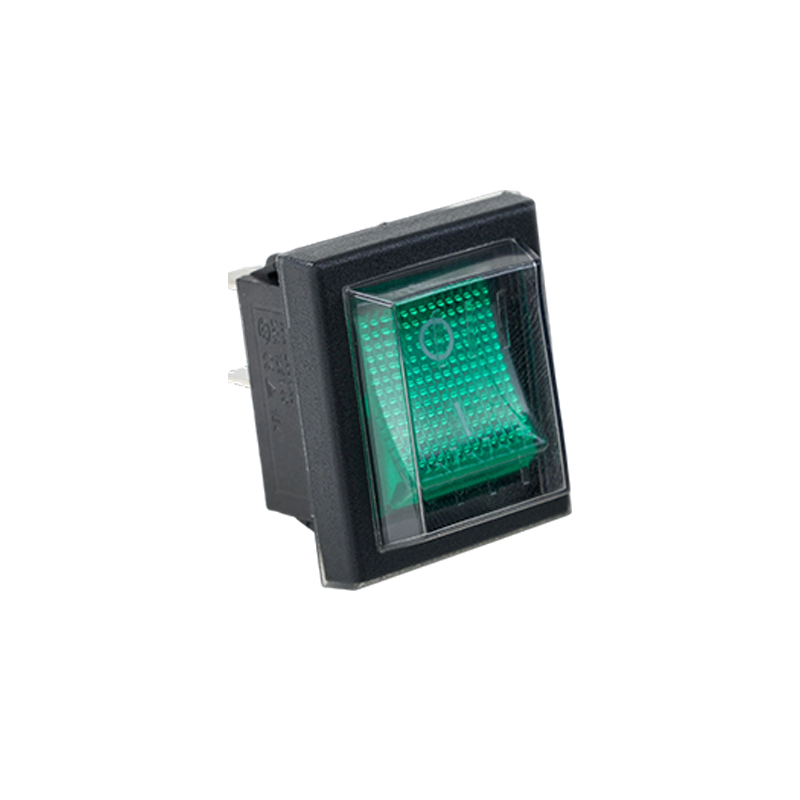

Green illuminated round rocker switch with single-pole, single-throw (SPST) contacts and o...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

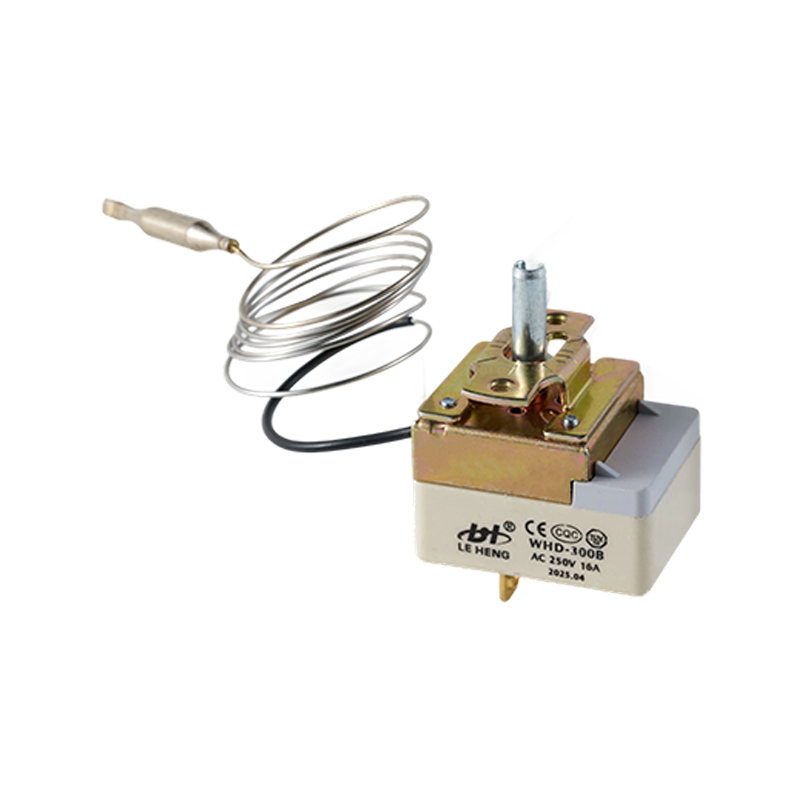

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

Rocker switches are widely used control components found in electrical appliances, temperature control devices, and various industrial systems. Their simple operation, reliable switching mechanics, and compatibility with different electrical loads make them essential in equipment such as heaters, thermoreats, capillary thermoreat switches, and temperature controller switches.

Overview of Rocker Switch Technology

A rocker switch is an electromechanical device used to open or close an electrical circuit. It operates by rocking a movable actuator back and forth, causing internal contacts to switch positions. Rocker switches are preferred for user-facing interfaces due to their intuitive operation and clear visual feedback.

Core Functions

- Circuit switching: Turns electrical circuits on or off.

- Control interface: Provides manual control for thermoreats, heating appliances, and process equipment.

- Status indication: Many rocker switches offer indicator lights to show operational status.

Common Usage

Rocker switches appear in many systems, including:

- Temperature controllers

- Capillary thermoreat switches

- General thermoreat switches

- Heating appliances

- Household electrical devices

- Industrial machinery and control panels

Major Classification Categories of Rocker Switches

Rocker switches can be categorized according to their electrical configuration, illumination, design structure, and application environment. Understanding these classifications helps engineers and technicians choose suitable switches for specific equipment.

Classification Based on Contact Configuration

The electrical contact configuration determines how many circuits a rocker switch can control and how they operate.

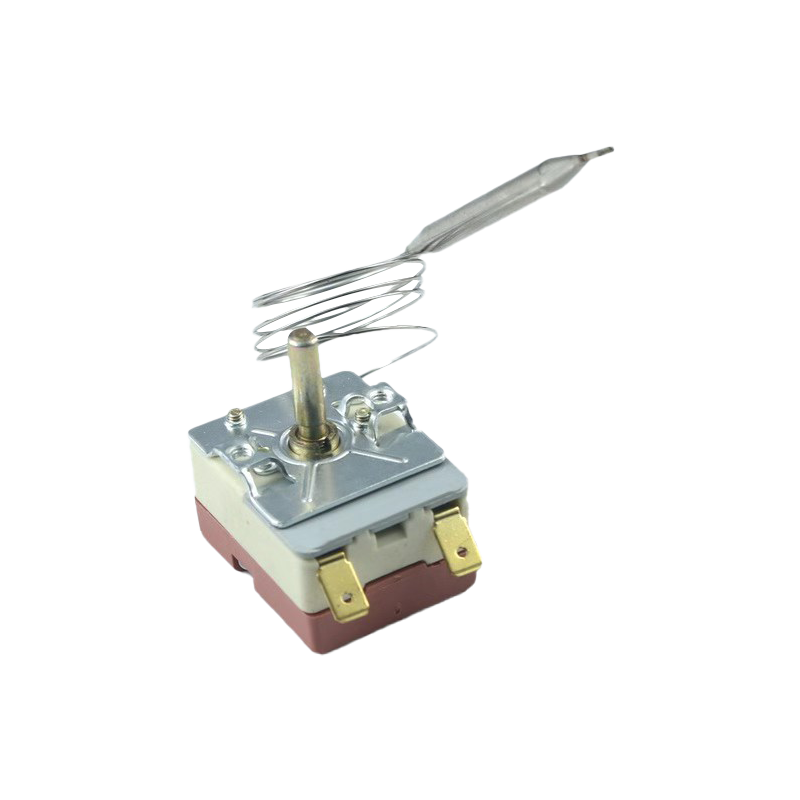

SPST (Single Pole Single Throw)

Controls one circuit with a simple ON/OFF function.

Common in heaters, temperature controller switches, and other basic control devices.

SPDT (Single Pole Double Throw)

Controls one input circuit with two output positions.

Useful for selecting between two modes or signal paths.

DPST (Double Pole Single Throw)

Controls two circuits simultaneously.

Frequently used in devices requiring dual-phase isolation for safety.

DPDT (Double Pole Double Throw)

Controls two circuits with two switching paths each.

Suitable for more complex systems requiring dual control modes or reversing operations.

Classification Based on Illumination

Illuminated rocker switches offer visual cues indicating operational status.

Non-Illuminated Rocker Switch

Simple design with no lighting element.

Often used in thermoreat switches and temperature controllers.

Indicator Light Rocker Switch

Includes built-in lamps such as:

- Neon indicators

- Small incandescent indicators

- LED indicators

These switches are helpful for equipment where users need a clear signal showing if heating, cooling, or electrical operation is active.

Classification Based on Mounting and Structural Style

Rocker switches vary in shape, size, and mounting type depending on their application.

Panel Mount Rocker Switch

Designed for installation on control panels.

Common in temperature controller switches and heating system interfaces.

Typically secured with clips or screw mounts.

Snap-In Rocker Switch

Fits into a pre-cut panel opening.

Quick installation and widely used in domestic appliances.

Waterproof or Splash-Resistant Rocker Switch

Protected with seal caps or encapsulated housing.

Suitable for environments with moisture exposure or steam, such as heating controls and kitchen equipment.

Miniature Rocker Switch

Compact size for small appliances.

Applied in portable heaters, compact temperature control modules, and electronic devices.

Classification Based on Application Purpose

Heating System Rocker Switch

Used in equipment such as:

- Capillary thermoreat switches

- Thermoreat housings

- Temperature controller switches

Provides simple, reliable manual control for heating activation or mode selection.

Industrial Control Rocker Switch

Often found in machinery, tools, and industrial automation systems.

Designed with enhanced durability and higher switching capacity.

Household Appliance Rocker Switch

Used in:

- Kitchen appliances

- Air-moving devices

- Electric ovens and toasters

- Small electrical equipment

Focuses on user-friendly operation and aesthetic integration.

Classification Based on Safety and Electrical Ratings

Low-Current Rocker Switch

Suitable for small loads such as indicator circuits or low-power temperature controllers.

Medium-Current Rocker Switch

Common in thermoreat switches controlling heaters or motors.

High-Current Rocker Switch

Designed for large heating equipment, compressors, or industrial loads.

Reinforced internal contacts for durability under heavy use.

Rocker Switch Components and Mechanisms

Rocker switches incorporate several essential parts:

Actuator

The visible portion users press to operate the switch.

Internal Contacts

Metal components that open or close the circuit.

Types may include:

- Silver alloy contacts

- Copper-based contacts

Housing

Made from insulated materials to protect users and internal components.

Illumination Assembly

Optional LED or lamp unit indicating switch status.

Terminals

Common terminal types include:

- Solder terminals

- Quick-connect terminals

- Screw terminals

Comparison Table: Rocker Switch Types

| Classification Basis | Switch Type | Key Features | Typical Use |

| Contact configuration | SPDT | Simple ON/OFF | Basic thermoreats, heaters |

| Contact configuration | SPDT | Two output positions | Mode selection |

| Illumination | Illuminated | Visual indication | Temperature controllers |

| Structure | Snap-in | Quick installation | Household appliances |

| Safety design | Waterproof | Moisture protection | Heating systems, kitchen appliances |

Applications in Thermoreat and Temperature Control Systems

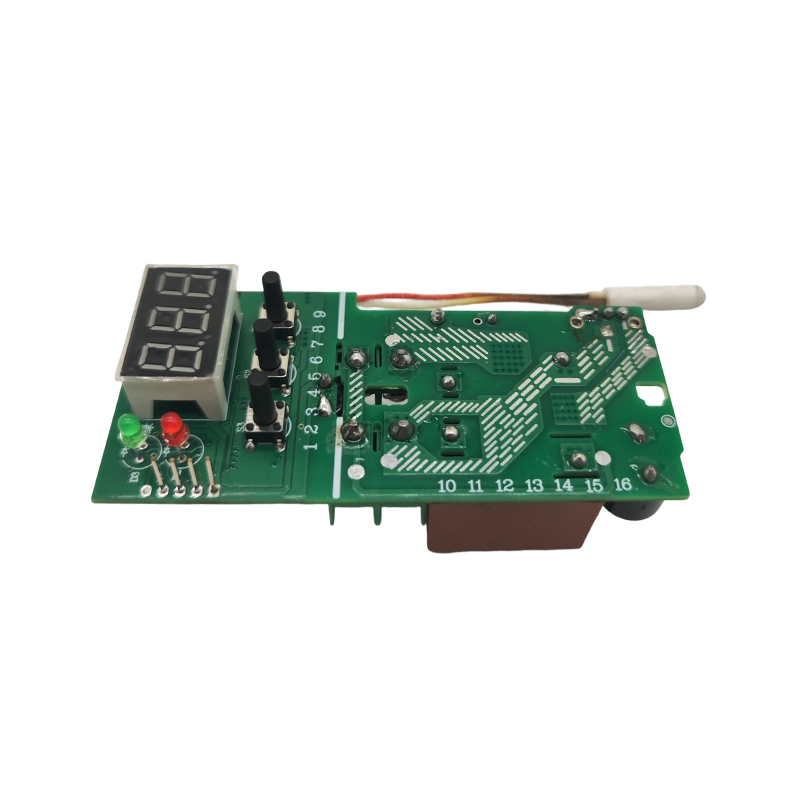

Rocker switches are often integrated into temperature regulation equipment. Examples include:

- Capillary Thermoreat Switches

Rocker switches act as system control interfaces for turning heating circuits on or off.

- Temperature Controller Switches

Provide manual command for temperature adjustment modes or power activation.

- General Thermoreat Switches

Allow users to override or activate heating elements manually when necessary.

The combination of thermoreatic sensing elements and rocker control interfaces provides a simple and effective temperature management solution.

Industry Trends and Developments

Rocker switch technology is evolving with new requirements in temperature regulation, control panels, and home appliances.

- Enhanced Material Durability

Modern switches use improved insulating materials for higher heat resistance.

- Energy Efficiency Integration

LED indicators are more common due to reduced energy consumption and longer service life.

- Increasing Demand for Custom Designs

Manufacturers adapt rocker switches for ergonomic interfaces, compact layouts, and improved usability.

- Environmental Adaptation

Water-resistant or dust-resistant rocker switches are gaining popularity in heating and ventilation systems.

Rocker switches play an important role in temperature control devices such as capillary thermoreat switches, thermoreat switches, and temperature controller switches. Through various classifications—such as contact configuration, illumination, structural design, and application purpose—rocker switches provide flexible control solutions across domestic, commercial, and industrial environments. Their simplicity, efficiency, and adaptability continue to support consistent and safe operation in modern electrical systems.

English

English Türk

Türk