The WHD-EM limit temperature controller is a highly reliable device for critical temperatu...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

Manual reset thermoreats, often referred to as safety limiters, play a critical role in protecting heating systems from unsafe temperature rise. Unlike automatic thermoreats that reset themselves once temperature returns to normal, manual reset types require human intervention to restore operation. This feature ensures that abnormal thermal conditions are investigated before a system is restarted, improving safety and operational reliability.

Overview of Manual Reset Thermoreat Technology

A manual reset thermoreat is a temperature-sensitive control device designed to interrupt a circuit when the monitored temperature exceeds the preset limit. It remains open until a technician or operator physically resets it. This characteristic makes the device suitable for applications where overheating may equipment damage, component fatigue, or safety risks.

Key Functions

- Over-temperature shutdown

Interrupts the power supply when temperature exceeds the setpoint.

- Manual recovery

Requires pressing a reset button to resume system operation.

- High reliability

Designed to ensure consistent performance over numerous thermal cycles.

Major Types of Manual Reset Thermoreats

Manual reset thermoreats can be categorized based on sensing mechanism, structural form, and application functions. The following sections provide an overview of the more commonly used variants in heating and industrial systems.

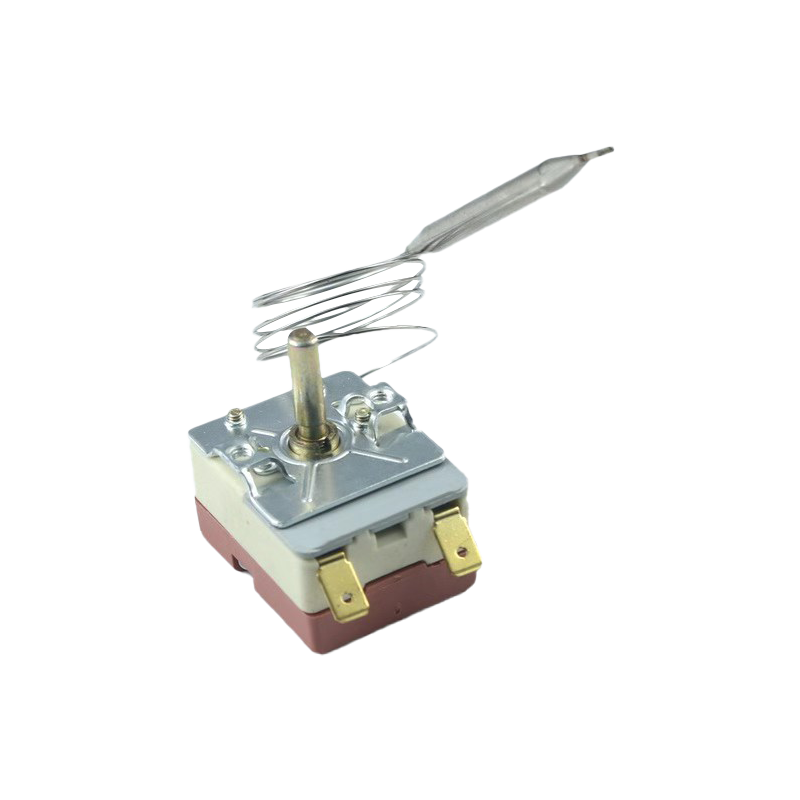

Manual Reset Capillary Thermoreat

Definition and Structure

A Manual Reset Capillary Thermoreat contains a fluid-filled sensing bulb and capillary tube connected to a mechanical switch. When temperature exceeds the preset threshold, the expansion of fluid changes internal pressure, triggering the switch to open.

Features

- Remote sensing capability via extended capillary tubing

- Suitable for large heating equipment where sensor must be located away from the control unit

- Stable thermal response for accurate limit control

- Manual reset button integrated into the main control body

Typical Applications

- Commercial water heaters

- Industrial heat processing equipment

- Large boilers

- Food service heating units

Advantages

- Flexible sensing placement

- Improved temperature sensitivity

- Applicable to both surface and immersion heating systems

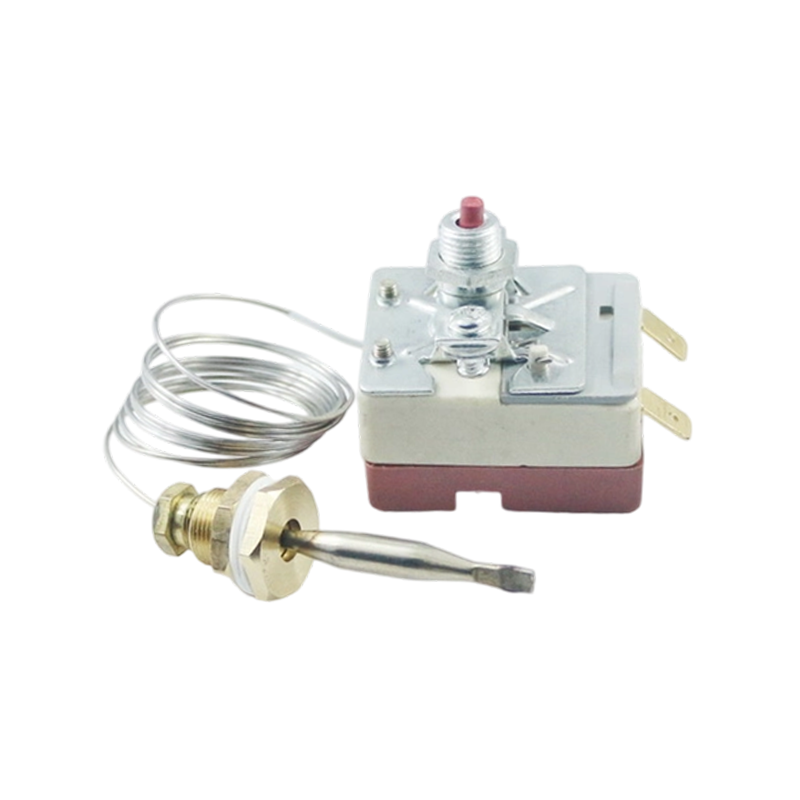

Manual Reset Limit Thermoreat

General Description

A Manual Reset Limit Thermoreat acts as a high-limit safety device. It triggers when temperature surpasses a predetermined threshold, ensuring the system remains off until manually reset.

Key Characteristics

- Fixed or adjustable temperature cutoff

- Snap-action mechanism for reliable circuit interruption

- Compact design suitable for various mounting styles

Applications

- Air heaters

- Oil or gas heating appliances

- Industrial drying systems

- Fan coil units

Benefits

- Straightforward construction

- Suitable for small or medium heating loads

- Provides protection against overheating caused by airflow blockage or component failure

Manual Reset Thermoreat (General Category)

Definition

This category includes a range of thermoreats with built-in manual reset mechanisms. They may use different sensing technologies, such as bimetal elements, capillary sensing, or electronic triggers.

Design Variants

Common forms include:

- Surface-mounted reset thermoreats

Installed on heating plates or metal surfaces.

- Immersion-type reset thermoreats

Used for liquid or fluid heating systems.

- Air-sensing reset thermoreats

Applied in ventilation or air-handling units.

Operating Principle

The thermoreat opens the circuit at a specified temperature. Once the equipment cools, the operator resets the system by pressing a button, lever, or switch on the housing.

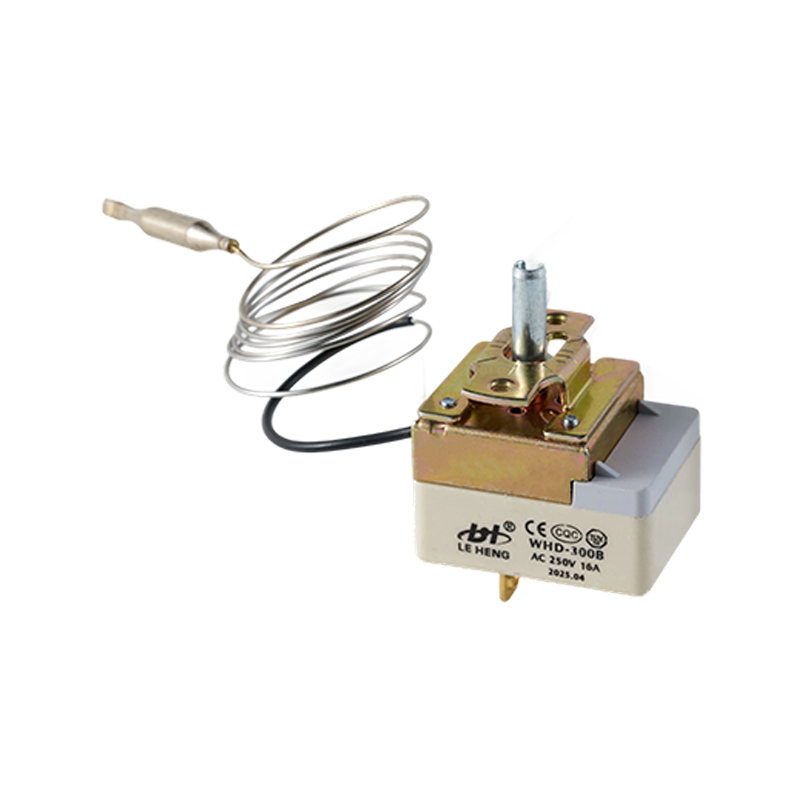

Capillary Reset Thermoreat

Classification Overview

A Capillary Reset Thermoreat belongs to the broader capillary sensing category but with manual reset functionality for over-temperature protection.

Construction

Components generally include:

- Sensing bulb

- Capillary tubing

- Pressure-actuated switch

- Manual reset actuator

- Terminal connections

Performance Attributes

- Can monitor temperature at a distance from the control housing

- Stable switching behavior due to fluid-pressure actuation

- Effective for systems requiring precise high-limit protection

Typical Uses

- Industrial ovens

- Electric boilers

- Thermal fluid systems

- High-power water heating units

Classification Summary Table

| Type of Manual Reset Thermoreat | Sensing Method | Reset Mode | Typical Application |

| Manual Reset Capillary Thermoreat | Bulb + capillary fluid | Manual | Large heaters, commercial boilers |

| Manual Reset Limit Thermoreat | Bimetal or mechanical | Manual | Air heaters, industrial fans |

| Manual Reset Thermoreat (General) | Bimetal or capillary | Manual | Heating appliances, HVAC |

| Capillary Reset Thermoreat | Bulb + capillary | Manual | Industrial ovens, fluid heaters |

Key Performance Parameters in Manual Reset Safety Limiters

Temperature Setpoint

More manual reset thermoreats operate with a fixed or factory-set temperature cutoff. Consistency in the limit point is essential for maintaining system protection.

Differential (Temperature Difference)

The differential defines how much cooling occurs before a reset is possible. A narrow differential promotes precise protection, while a wider differential helps avoid frequent activation.

Sensor Placement Flexibility

Capillary variants offer extended sensing distances, whereas surface-mounted designs suit compact systems.

Switching Capacity

Manual reset thermoreats must match the electrical load of the equipment, especially in systems with frequent cycling or high inrush currents.

Environmental Resistance

Depending on the environment, thermoreats may require forms of resistance such as:

- Moisture resistance

- Vibration resistance

- Chemical exposure tolerance

Application Fields Across Heating and Safety Systems

Manual reset thermoreats are widely used in heating and industrial sectors due to their safety functions. Common application fields include:

- Water heating and storage tanks

- Commercial and industrial boilers

- Food processing equipment

- Air heating units

- Laboratory thermal systems

- Heat exchangers and thermal circulation units

- Electric heating panels and convection units

In each area, the thermoreat acts as a safety barrier to prevent overheating and maintain operational stability.

Industry Trends and Development Directions

As heating and thermal systems evolve, manual reset thermoreats are gradually incorporating improvements that enhance adaptability and reliability.

Advanced Sensor Materials

New sensing materials aim to improve thermal response stability under different operating conditions.

Enhanced Mechanical Durability

Modern switch designs may offer improved resistance to wear, ensuring long-term use in high-temperature cycles.

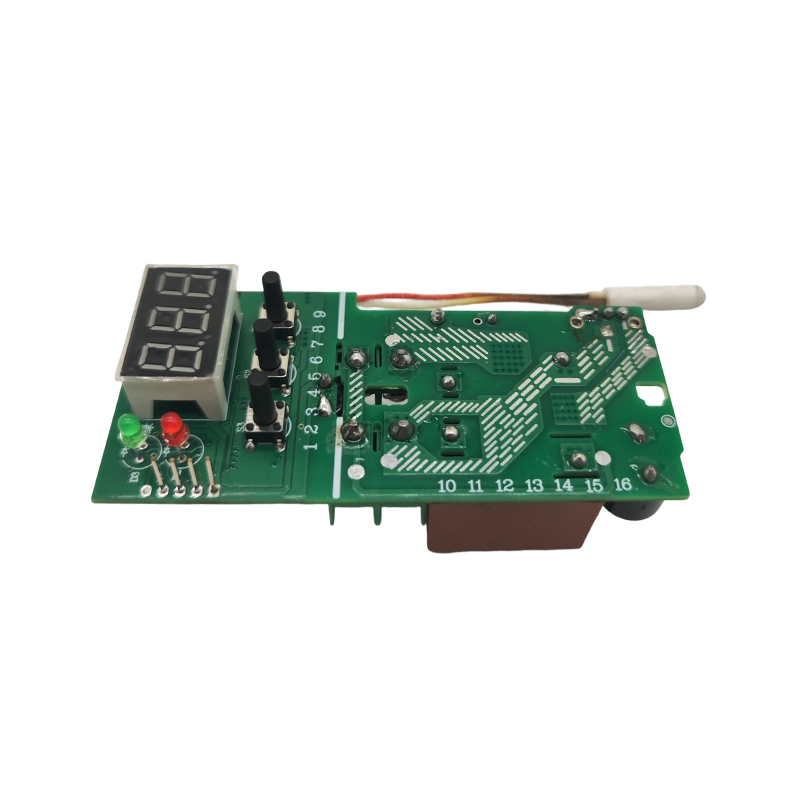

Integration with Electronic Systems

Some systems pair manual reset thermoreats with digital temperature monitors to provide additional feedback and diagnostic capabilities.

Manual reset thermoreats—such as Manual Reset Capillary Thermoreats, Manual Reset Limit Thermoreats, Manual Reset Thermoreats, and Capillary Reset Thermoreats—serve as essential safety limiters in heating and industrial systems. Their ability to interrupt circuits during over-temperature conditions and require manual intervention for restart enhances operational safety and protects equipment from thermal stress.

English

English Türk

Türk