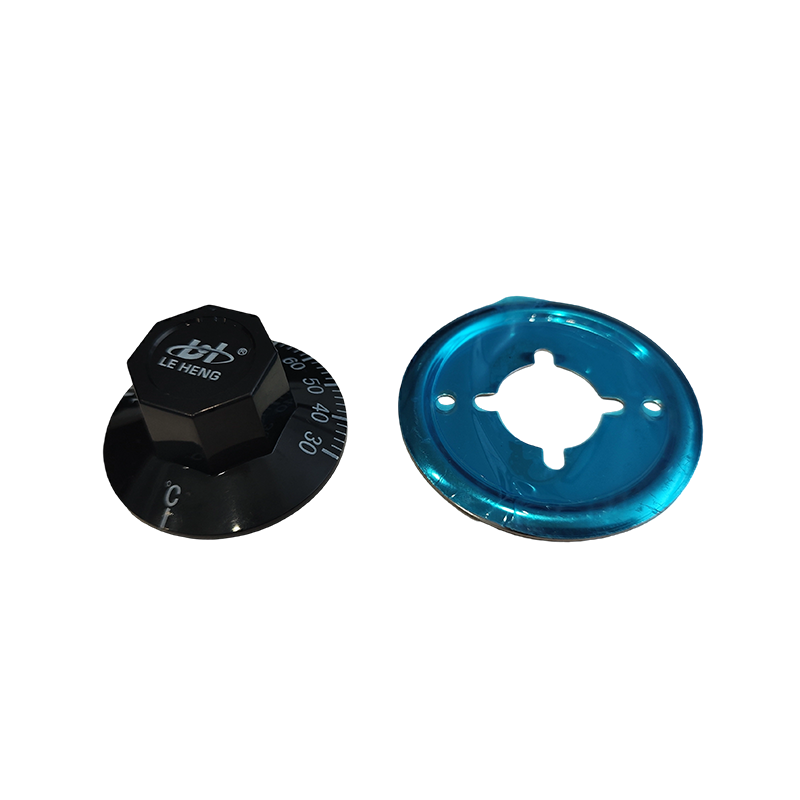

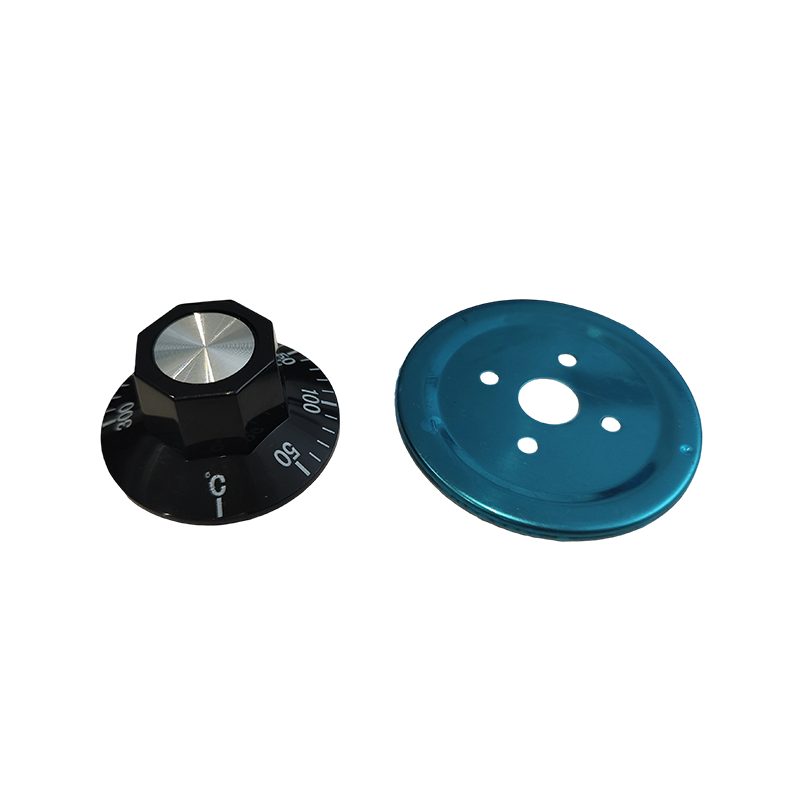

An eight-sided knob, often used in control systems, offers precise adjustment of parameter...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

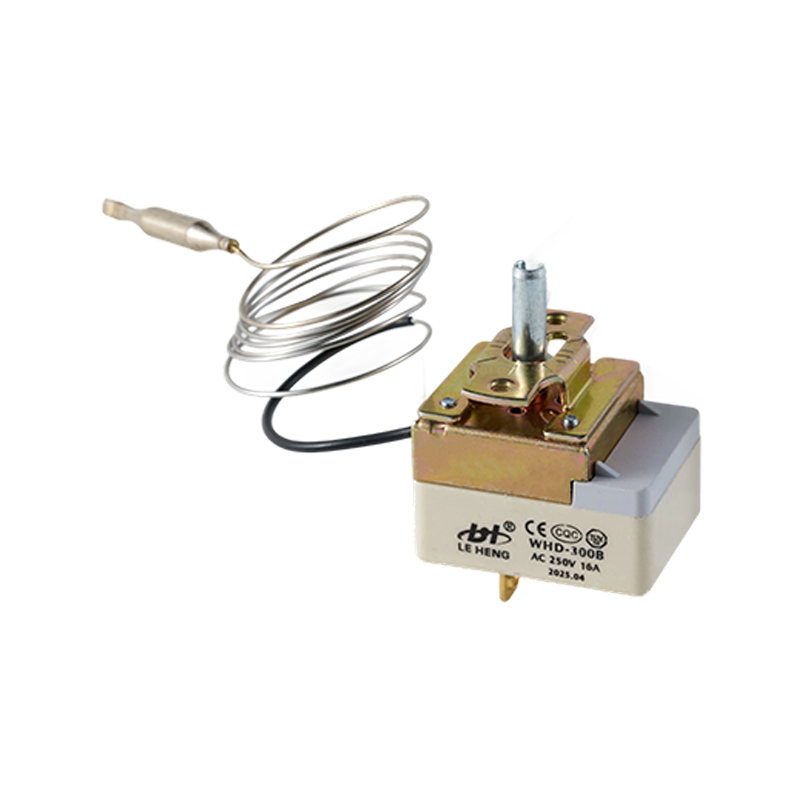

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

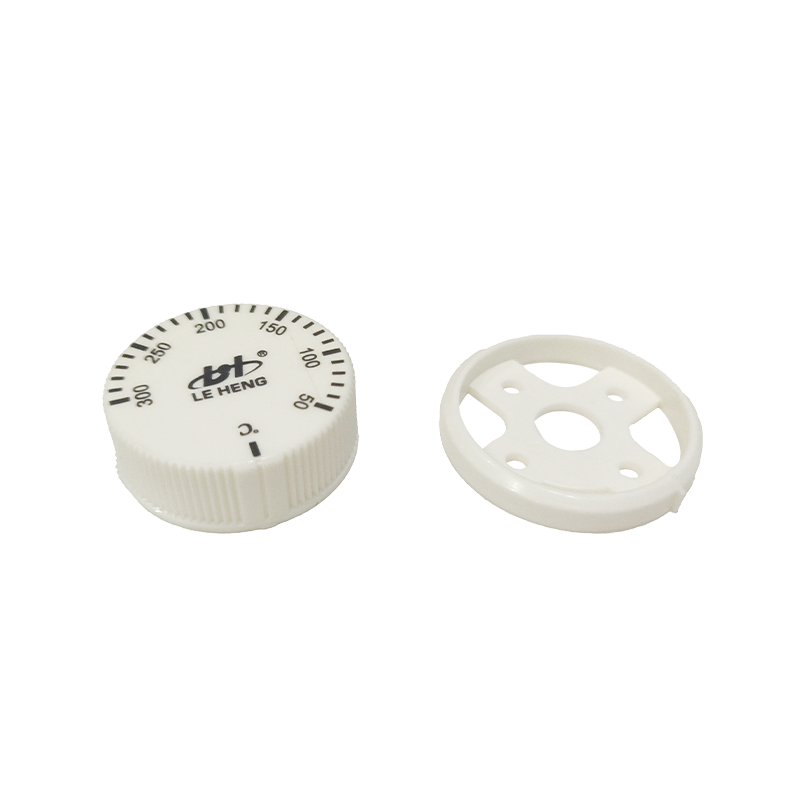

Thermoreat knobs are essential components used to manually adjust temperature settings in a wide range of heating, cooling, and environmental control equipment. Whether functioning alongside a capillary thermoreat, an adjustable mechanical thermoreat, or a temperature controller, the knob provides users with a direct and intuitive interface for regulating system performance.

Overview of Thermoreat Knob Technology

A thermoreat knob is a mechanical control element mounted onto a thermoreat shaft or spindle. By rotating the knob, users change the thermoreat’s setpoint, altering heating or cooling output according to application requirements.

Primary Functions

- Temperature Adjustment

Users manually select temperature levels by rotating the knob.

- User Interface

Provides a simple, clear method to control the thermoreat without digital programming.

- Scale Indication

Many knobs include printed or molded graduations that represent temperature or operating levels.

- Panel Integration

Knobs visually complement control panels and maintain a consistent user experience.

Major Categories of Thermoreat Knobs

Thermoreat knobs can be grouped by construction type, application, temperature adjustment method, and mounting style. Below are the primary classifications used across heating and temperature control industries.

General Thermoreat Knob

Description

A general Thermoreat Knob is designed for standard mechanical thermoreats used in home appliances, heating equipment, or simple temperature controllers. It usually mounts directly to the thermoreat’s shaft.

Features

- Rotational control for temperature adjustment

- Small form factor for compact devices

- Printed numbers or symbols for user guidance

- Suitable for both heating and cooling systems

Typical Applications

- Space heaters

- Water heater control panels

- Portable heating devices

- Cooking appliances

- Small HVAC units

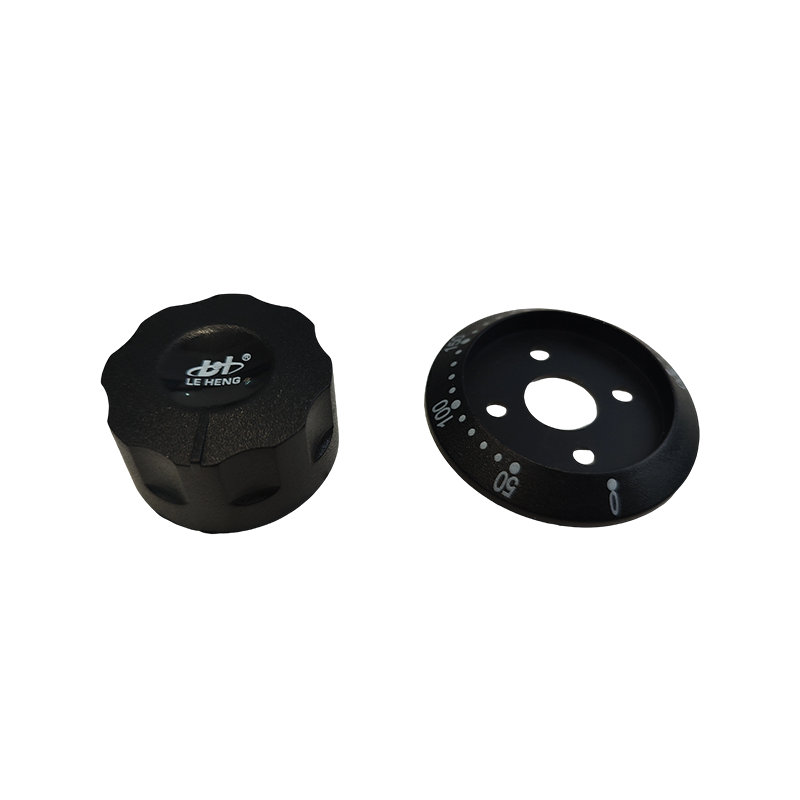

Capillary Thermoreat Knob

Definition

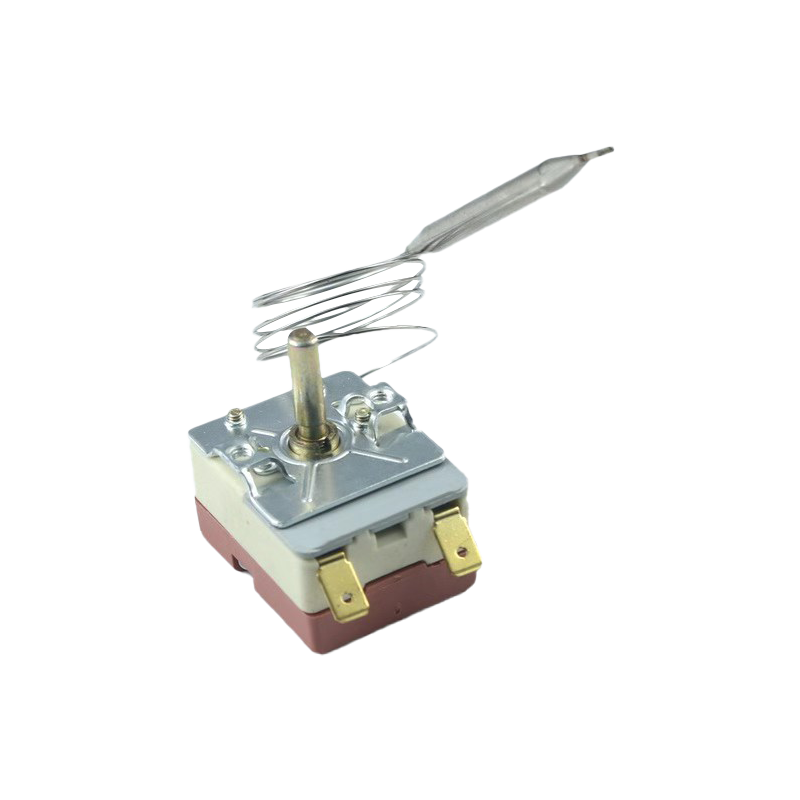

A Capillary Thermoreat Knob is used together with a capillary thermoreat, which includes a sensing bulb and a fluid-filled capillary tube. The knob adjusts the mechanical setpoint of the thermoreat’s internal switch.

Design Considerations

Because capillary thermoreats are frequently used in industrial and commercial heating systems, the knobs must be:

- Sturdy and heat-resistant

- Able to integrate with panel-mounted thermoreat housings

- Compatible with longer or more robust shafts

Where They Are Used

- Commercial kitchen equipment

- Boilers and heating units

- Industrial ovens

- Water storage heaters

- Heat processing machinery

Benefits

- Smooth rotational adjustment

- Clear temperature scaling

- Reliable user feedback during operation

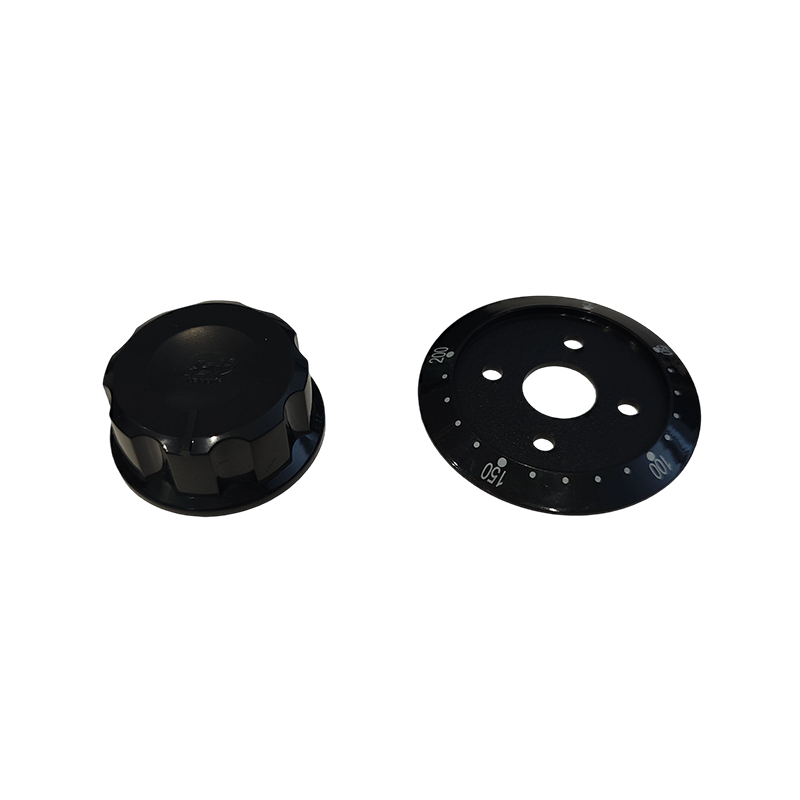

Adjustable Thermoreat Knobs

Overview

Adjustable Thermoreat Knobs enable a wide range of temperature selections and are commonly paired with mechanical thermoreats used in consumer and commercial equipment.

Features

- Large adjustment range

- Often paired with multi-level temperature scales

- May include stops or detents to support precise control

- Suitable for thermoreats with variable settings

Applications

- Refrigeration and cooling units

- Heating appliances

- Food equipment with multiple temperature zones

- Environmental control cabinets

Advantages

- Versatile and user-friendly

- Suitable for devices requiring repeatable temperature adjustments

- Designed for long-term mechanical durability

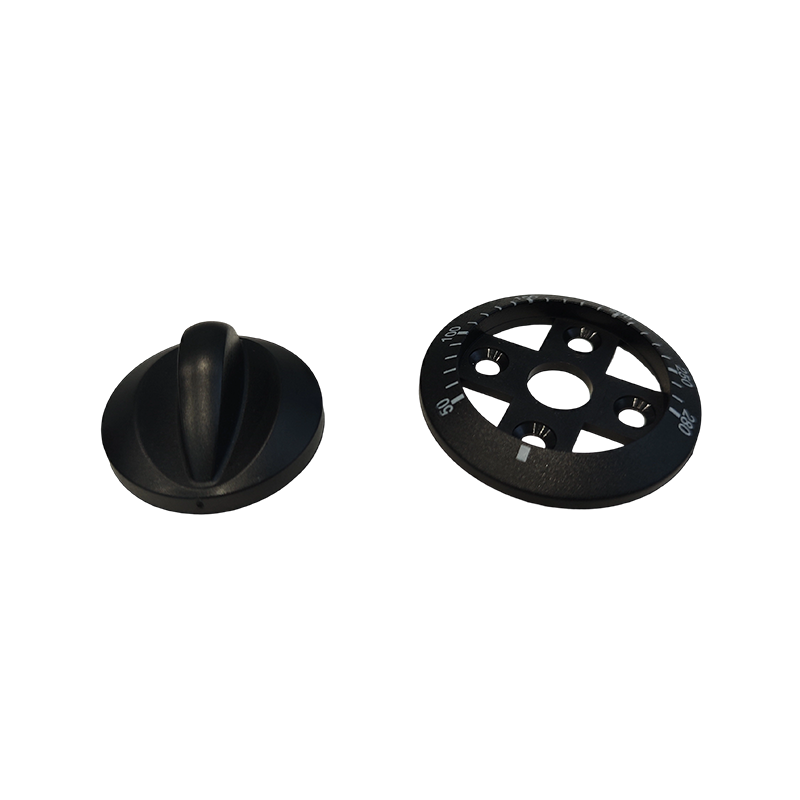

Classification Based on Structural and Mechanical Design

Thermoreat knobs come in various structural designs depending on control requirements and installation constraints.

Standard Round Knobs

- The more common type

- Easy gripping and smooth rotation

- Suitable for universal thermoreat shaft shapes

Pointer Knobs

- Include a pointer for accurate alignment with scale markings

- Ideal for applications requiring precise temperature selection

Recessed Knobs

- Installed within a protective control panel opening

- Designed to avoid accidental adjustment

- Common in commercial equipment where settings should remain stable

Knobs with Push-and-Turn Mechanics

- Used in systems requiring user confirmation before changing settings

- Useful for safety-sensitive heating appliances

Classification Based on Mounting Method

Different installation methods accommodate diverse design and functional needs.

Set-Screw Knobs

- Secured to the shaft using a small screw

- Provide strong holding force

- Used in equipment subject to vibration or frequent operation

Push-On Knobs

- Simply pressed onto a compatible shaft

- Quick installation

- Common in consumer appliances

D-Shaft and Splined Knobs

- Designed for thermoreats with matching shaft geometry

- Offer secure fit without required hardware

- Support precise alignment of setpoint indicators

Material Classifications

Thermoreat knobs must withstand continuous handling, heat exposure, and environmental factors.

Thermoplastic Knobs

- Lightweight and cost-effective

- Often used in domestic appliances

- Resistant to heat within standard operating temperatures

Reinforced Plastic Knobs

- Improved resistance to heat, chemicals, and mechanical stress

- Suitable for commercial or industrial environments

Metal-Based Knobs

- Less common but used where durability and heat tolerance are key

- Ideal for heavy-duty heating systems

Comparative Summary Table

| Knob Type | Key Features | Typical Use | Adjustment Style |

| Thermoreat Knob | Basic control, simple scale | Home appliances | Manual rotation |

| Capillary Thermoreat Knob | Robust, heat-resistant | Industrial heaters | Panel-mounted rotation |

| Adjustable Thermoreat Knob | Wide temperature range | Cooling & heating units | Precision adjustment |

Application Fields Across Industries

Thermoreat knobs are used in various equipment categories, including:

Heating Appliances

- Space heaters

- Electric heaters

- Oil heaters

Water Heating and Fluid Control

- Residential water heaters

- Commercial hot water systems

Food-Service and Cooking Equipment

- Ovens

- Grills

- Warming appliances

Industrial Temperature Control Systems

- Heat treatment equipment

- Processing ovens

- Commercial boilers

Refrigeration and Cooling Units

- Adjustable cooling cabinets

- Temperature-controlled storage systems

Development Trends in Thermoreat Knob Design

As equipment design evolves, thermoreat knobs also undergo improvements in functionality, durability, and aesthetics.

- Enhanced Ergonomics

More refined shapes for improved grip and smoother rotation.

- Higher Heat Resistance

Materials are optimized for prolonged exposure to elevated temperatures.

- Improved Scale Accuracy

Clearer markings for more reliable temperature selection.

- Modular Designs

Knobs are increasingly developed to fit multiple shaft styles and control modules.

Thermoreat knobs—whether general thermoreat knobs, capillary thermoreat knobs, or adjustable thermoreat knobs—play a crucial role in providing accurate and intuitive temperature control across a wide range of appliances and industrial systems. Their structural variations, materials, and mounting methods are designed to meet diverse performance requirements.

English

English Türk

Türk