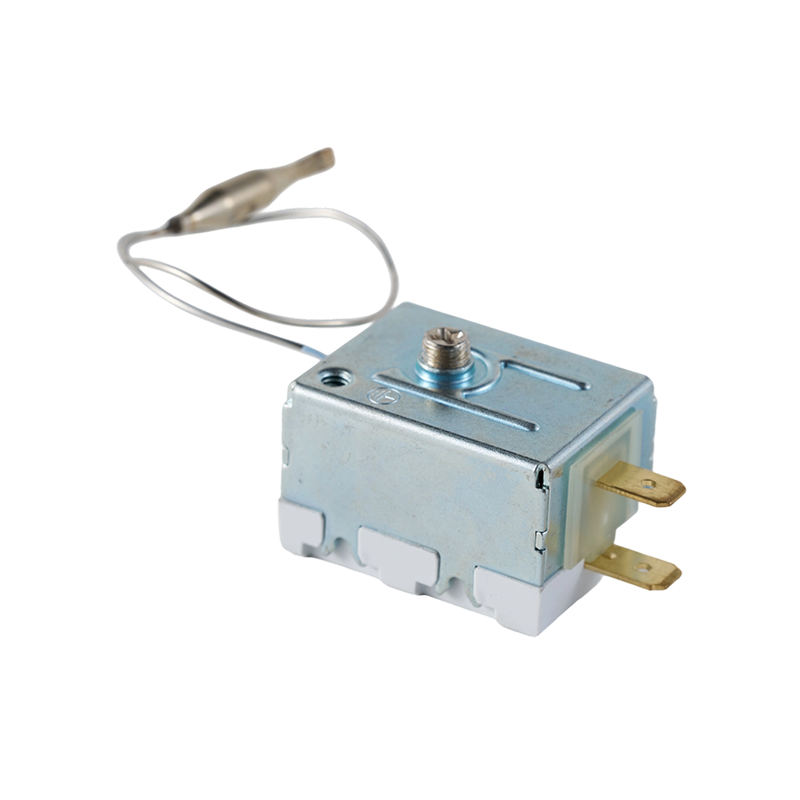

The WHD-H2 oven heating limiter is designed for precise temperature control, with a maximu...

-

Spring has arrived, and all things are flourishing. Our resumption of work conference concluded successfully amidst enthusiasm and focus, marking the official start of a new journey in 2026. Returning...

READ MORE -

A limit thermostat is a crucial safety component found inside furnace systems, designed to monitor internal heat levels and prevent overheating. Within a furnace, the limit thermostat helps maintain s...

READ MORE -

A limit thermostat and a normal thermostat are both temperature-related components found in heating systems, but their responsibilities are very different. The limit thermostat focuses on safety prote...

READ MORE -

A limit thermostat is often mentioned alongside standard temperature controllers, yet the two devices serve very different purposes within heating systems. The limit thermostat operates as a protectiv...

READ MORE -

A limit thermostat plays a critical role in heating systems by monitoring internal temperatures and acting as a safety control when abnormal heat conditions occur. Unlike comfort-focused temperature c...

READ MORE

Heating systems used in residential, commercial, and industrial environments require reliable protection mechanisms to prevent overheating and maintain stable operation. While thermoreats regulate temperature during normal operation, heating-temperature-limiters provide an essential safeguard by interrupting power when temperatures exceed safe values. These devices are critical components in systems where elevated temperatures can cause equipment damage or reduce operational lifespan.

Introduction to Heating Temperature Limiters

A heating-temperature-limiter is a protective device designed to detect abnormal temperature rise and disconnect electrical circuits to prevent overheating. Unlike standard thermoreats that cycle heating systems on and off during normal operation, limiters activate only when temperature exceeds a defined threshold.

These devices are widely used in heating appliances, industrial machines, water heating systems, and thermal equipment that must not exceed a specific temperature for safety or performance reasons.

Key objectives of heating-temperature-limiters include:

- Avoiding damage to heating components

- Preventing thermal stress on equipment

- Improving system reliability

- Maintaining safe operating conditions

- Complying with industrial safety standards

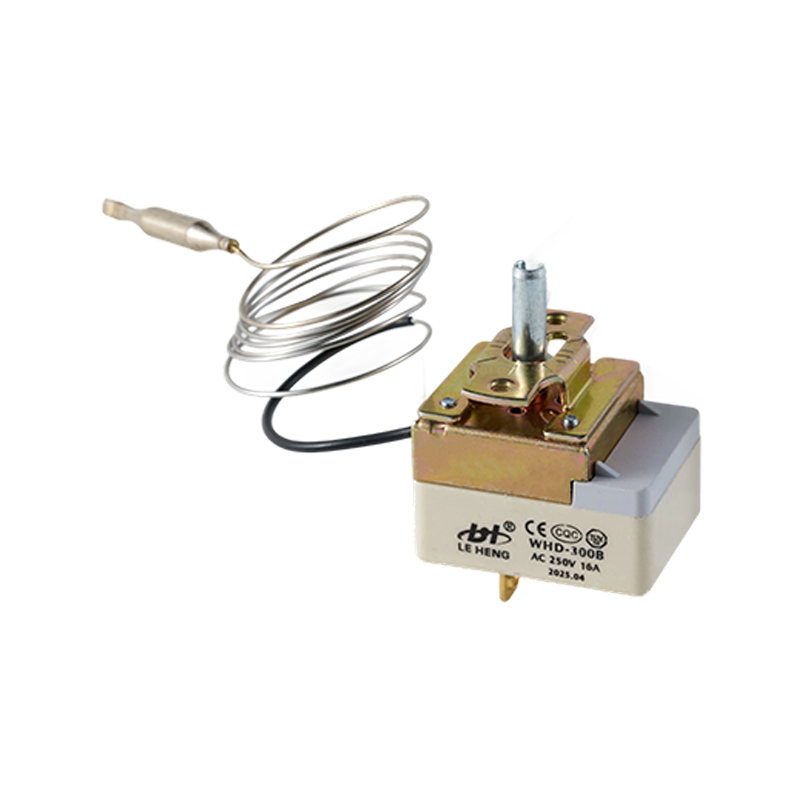

Limit Temperature Controller

A Limit Temperature Controller is a protective device designed to monitor temperature and disconnect heating elements when a preset limit is reached. These controllers often incorporate both sensing and switching components in one unit. Their limit setpoint is typically factory calibrated or user-defined through a secure mechanism to prevent accidental adjustment.

Main Characteristics

- Fixed or controlled limit setting

The allowable temperature limit is determined by design to ensure consistency.

- Manual or automatic reset

Manual reset versions require user intervention to restore operation.

Automatic reset models re-engage once temperature returns to normal.

- Reliable over-limit cutout

The device disconnects power quickly when conditions exceed the threshold.

Common Applications

Limit Temperature Controllers are widely used where controlled heating cycles are important but require an independent layer of protection. Applications include:

- Water heating systems

- Heat-recovery units

- Industrial processing equipment

- Electric heating machinery

- Environmental simulation devices

These controllers provide a stable and essential safety function, ensuring that equipment remains within designed thermal boundaries.

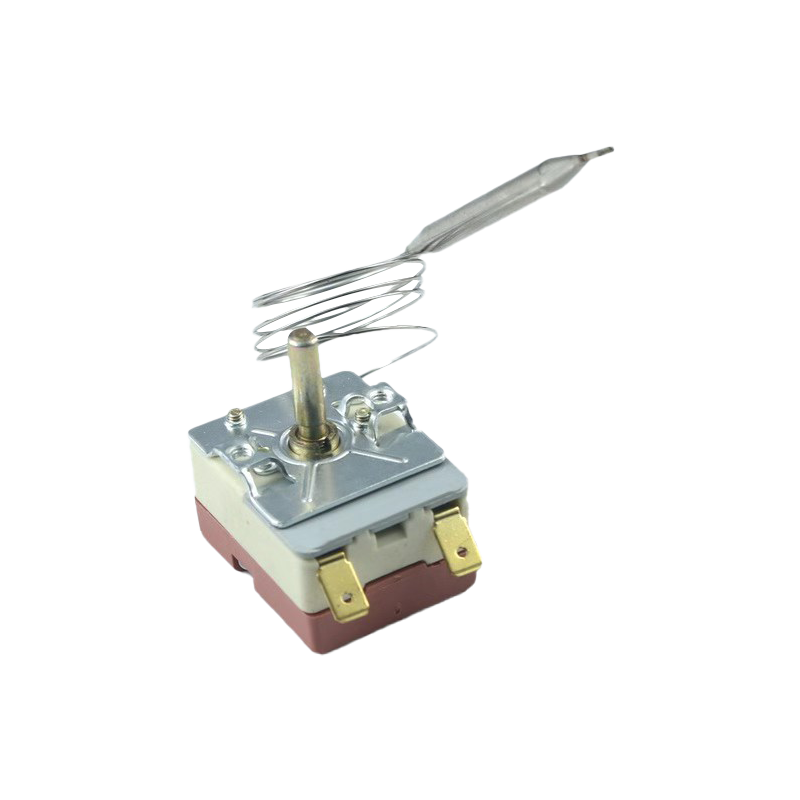

Limit Thermoreat

A Limit Thermoreat is a temperature-limiting device that interrupts electrical circuits when a fixed limit is exceeded. Unlike standard thermoreats used for continuous temperature regulation, a Limit Thermoreat operates only when the system temperature surpasses a predetermined big.

Structural Features

more Limit Thermoreats include:

- A sensing element such as a bimetal disc or capillary bulb

- A switch mechanism that opens when limit temperature is reached

- A reset function, either manual or automatic

The design emphasizes durability and repeatable response to avoid variation in protection levels.

Distinct Functional Notes

- Does not modulate temperature during normal operation

- Serves strictly as a safety limiter

- Often used together with standard thermoreats for dual-layer protection

Common Use Cases

Limit Thermoreats are common in:

- Industrial dryers

- Heating ventilation equipment

- Boilers and water heaters

- Electric furnaces

- Commercial kitchen appliances

They serve as a final protective measure, safeguarding the equipment even if a controlling thermoreat fails or becomes inaccurate.

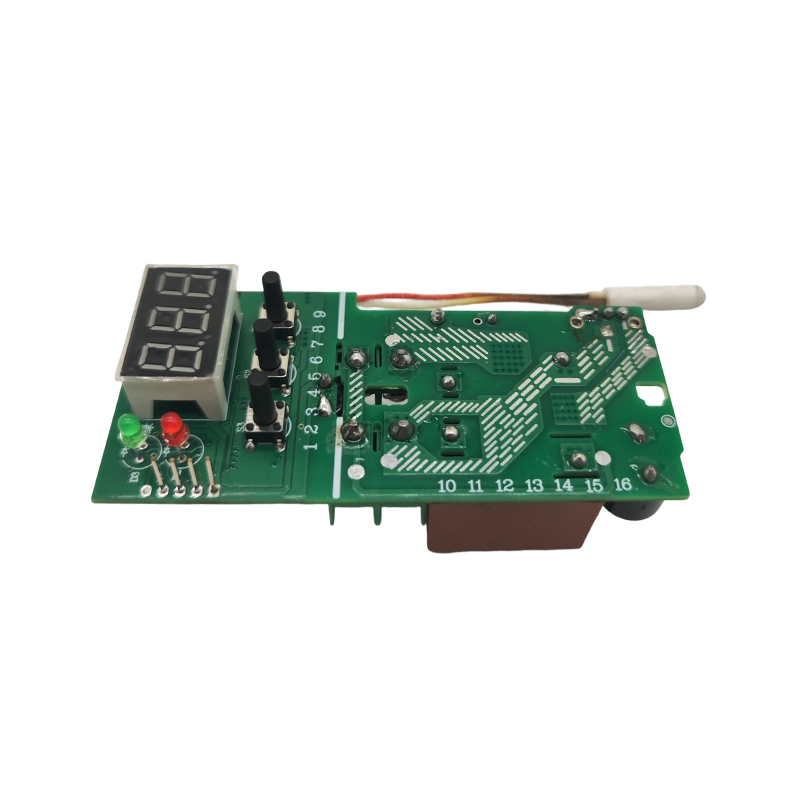

Temperature Control Switch

A Temperature Control Switch is a basic thermal protection and control device used to open or close a circuit based on temperature conditions. It may serve as a temperature controller, limiter, or simple switch depending on how it is calibrated and installed.

Functional Roles

Depending on design, a Temperature Control Switch can provide:

- Basic temperature control (on/off heating regulation)

- Over-temperature protection (limit switching)

- Auxiliary switching (activating fans or alarms)

The versatility of this device makes it valuable in both household and industrial thermal systems.

Characteristic Features

- Designed for simple integration

- Mechanical or electronic switching

- Fixed setpoints or adjustable depending on model

- Works with heating, cooling, or mixed-function systems

Typical Application Scenarios

- Small heating units

- Commercial warming devices

- Heat-sensitive processing machines

- Thermal protection circuits in appliances

Its structural simplicity and functional flexibility support a wide range of temperature-managed systems.

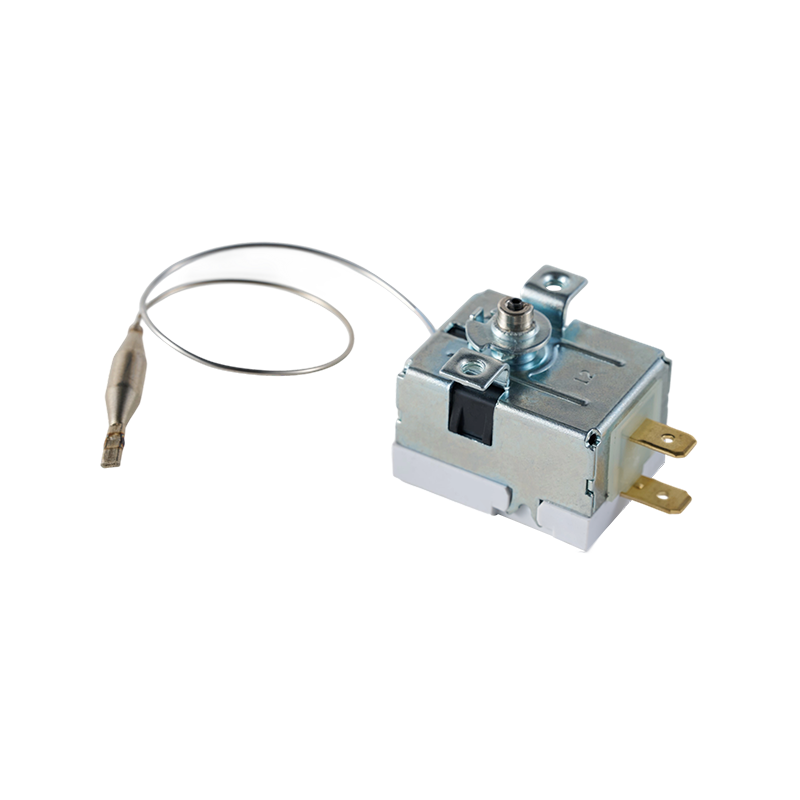

Temperature Limiter Thermoreat

The Temperature Limiter Thermoreat is a specialized thermoreat engineered primarily to prevent overheating. It differs from general thermoreats because its setpoint is fixed and often cannot be changed by users. Once the system exceeds the limit, the thermoreat disconnects the circuit and prevents heating from continuing until conditions become safe.

Key Characteristics

- Fixed temperature limit: Ensures consistent protective response

- Reset requirement: Many models use manual reset for enhanced safety

- High stability: Designed for stable operation under repeated thermal cycling

Typical Applications

This device is widely used in:

- Electric heating tubes

- Heat exchange equipment

- Thermal protection in industrial systems

- Water heating devices

- Commercial heating appliances

The Temperature Limiter Thermoreat ensures that an independent protective mechanism exists even if other control components malfunction.

Technical Comparison of Heating-Temperature-Limiter Categories

A simplified comparison is shown below to outline core distinctions among the four limiter types:

| Category | Main Function | Adjustability | Reset Method | Common Use |

| Limit Temperature Controller | Over-limit control | Limited | Auto or manual | Water heaters, industrial systems |

| Limit Thermoreat | Safety cutout | Fixed | Auto or manual | Heating appliances, ventilation units |

| Temperature Control Switch | Control or limit switch | Adjustable or fixed | Auto | General heating and protection |

| Temperature Limiter Thermoreat | Over-temperature safety | Fixed | Often manual | Heat-sensitive industrial equipment |

Although their functions overlap, each category serves a specific role, and selecting the correct type is essential for safe heating-system design.

Working Principles of Heating-Temperature-Limiters

Heating-temperature-limiters operate based on thermal sensing elements that respond to temperature changes. The mechanisms vary depending on the design but generally rely on:

Bimetal Sensing Mechanism

A metallic disc contains two bonded metals with different expansion rates.

At a designated temperature, the disc rapidly snaps, opening a switch.

This method provides reliable and repeatable cutout performance.

Capillary Sensing Mechanism

A liquid-filled bulb and tube expand with rising temperature.

Pressure changes activate a switch to interrupt the circuit.

Capillary systems allow sensing at remote points.

Electronic Sensing Mechanism

Temperature sensors such as thermistors or RTDs detect heat changes.

An electronic circuit triggers a relay to interrupt power.

Often found in systems requiring stable and precise limit control.

Each sensing method offers advantages depending on environmental conditions, system layout, and precision requirements.

Industrial Applications of Heating-Temperature-Limiters

Heating-temperature-limiters play an essential role across several industries. Their ability to reliably interrupt heating circuits protects equipment from expensive damage and ensures long operating life.

HVAC and Air Handling Equipment

Temperature limiters protect heating elements and prevent overheating in:

- Air handlers

- Duct heaters

- Electric furnaces

- Heat pump auxiliary heaters

Water Heating and Plumbing Systems

Limiters safeguard systems including:

- Electric water heaters

- Tankless heating units

- Hot-water circulation systems

Protection is vital to avoid thermal stress or structural wear.

Industrial Process Heating

Industries rely on temperature limiters for:

- Industrial ovens

- Dryers

- Processing chambers

- Heat-based manufacturing equipment

Maintaining safe temperature ceilings prevents damage to machinery and processed materials.

Food Service and Commercial Equipment

In food-service applications, limiters ensure safety and heating stability in:

- Warming cabinets

- Ovens

- Cookers and grills

- Food preparation stations

Heat consistency and safety remain a priority in these environments.

Selection Considerations for Heating-Temperature-Limiters

When choosing a limit device for thermal systems, engineers often evaluate the following factors:

Temperature Range and Limit Setting

The limit threshold must align with the system’s safe operating range.

Reset Mechanism

Manual reset for safety-critical systems

Automatic reset for convenient restart in non-hazard environments

Environmental Conditions

Consider:

- Ambient temperature

- Vibration

- Humidity

- Installation orientation

Switching Load Capacity

Match limiter contact ratings to the system’s voltage and current requirements.

Sensing Method

Choose between bimetal, capillary, or electronic sensing based on precision and layout needs.

Heating-temperature-limiters serve a vital role in protecting thermal systems from overheating and ensuring long-term reliability. The four major categories—Limit Temperature Controllers, Limit Thermoreats, Temperature Control Switches, and Temperature Limiter Thermoreats—provide different levels of control and protection, from basic limit cutout to advanced safety functionality.

English

English Türk

Türk