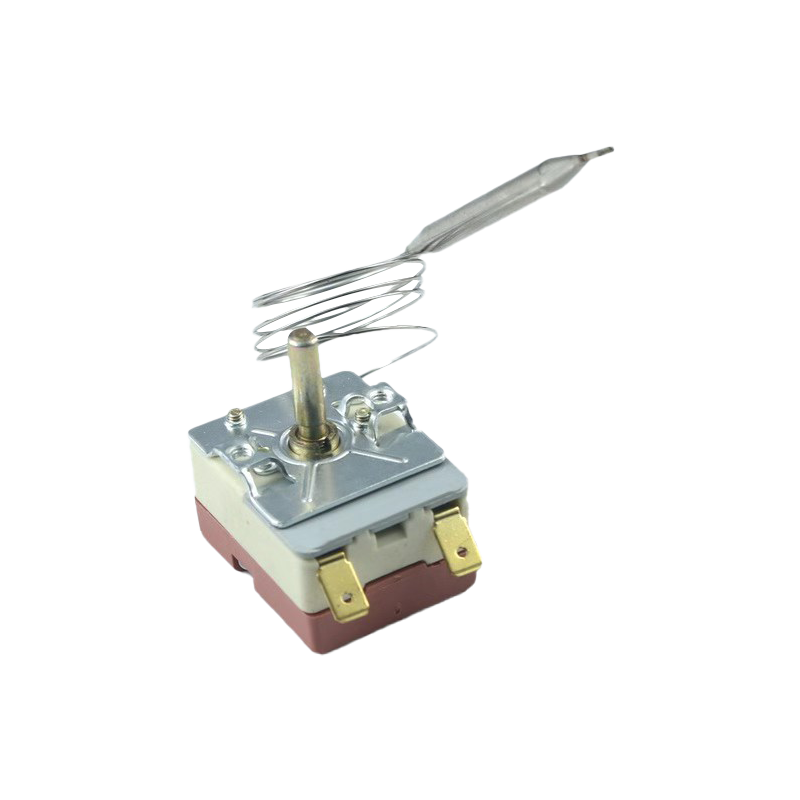

WHD-E copper adjustable copper capillary thermostat is a mechanical temperature regulating devic...

Capillary Thermostat China: Usage Scenarios and Safety Requirements in Various Devices

A Vital Component Across Industries

Within the intricate workings of countless appliances and systems, a small but critical device ensures operational safety and efficiency—the capillary thermostat China. Sourcing these components often leads to the robust manufacturing ecosystem found in the capillary thermostat of China. This exploration details the diverse applications of these thermostats and outlines the essential safety requirements that govern their use, providing a framework for understanding their role in global supply chains.

Primary Application Domains

The utility of a capillary thermostat extends across a broad spectrum of devices, each presenting a distinct operational environment. In the realm of household appliances, they are fundamental. Refrigerators and freezers rely on them for consistent interior temperature management and controlling defrost cycles, while electric water heaters use them to regulate water temperature and prevent overheating. Smaller appliances, from coffee makers to portable heaters, also depend on these thermostats for basic thermal control.

Beyond the home, commercial and industrial applications present more demanding conditions. Commercial refrigeration units, beverage coolers, and medical storage equipment require thermostats that offer consistent performance over extended periods. In industrial settings, they can serve as protective devices for motors or transformers, activating to prevent damage from excessive heat. Automotive applications, such as auxiliary heaters or battery thermal management systems, introduce further challenges like vibration and wider ambient temperature fluctuations.

Fundamental Safety Considerations and Certifications

Given this wide range of applications, adherence to established safety requirements is not just a preference but a necessity. These requirements address both universal electrical safety and application-specific hazards. Core electrical parameters include sufficient dielectric strength to prevent current leakage, appropriate insulation resistance, and physical creepage distances to ensure safe operation at rated voltages.

International safety certifications provide a verified roadmap for compliance. Products intended for North American markets typically require evaluation to UL or cUL standards. For the European Union, the CE marking, often supported by specific norms like those from VDE, indicates conformity with health, safety, and environmental protection directives. Other regions may have their own standards, such as China's CCC. These certifications involve rigorous testing of materials, construction, and performance under fault conditions.

Furthermore, specific applications dictate additional safety considerations. A thermostat for a water heater, for instance, must be designed to handle high-pressure environments and may incorporate a manual reset function as a critical safety lockout. Devices used in refrigeration circuits must be sealed to prevent refrigerant leakage and constructed to avoid sparks in potentially flammable atmospheres.

Guidance for Manufacturers and Global Buyers

For manufacturers within the capillary thermostat China landscape, integrating these safety principles from the initial design phase is crucial. Selecting materials with suitable thermal and electrical properties, designing robust mechanical structures, and planning for the necessary certification processes are all integral to producing compliant and reliable components.

For international buyers and engineers, a clear understanding of the end device's operational environment and target market is the one step. When engaging with suppliers, inquiries should move beyond basic specifications to explicitly ask about relevant safety certifications. Requesting copies of test reports or certification documents, and understanding the testing parameters they cover, provides tangible evidence of a product's safety compliance. Confirming that a component is rated for the specific electrical load and environmental conditions of its intended application is a fundamental aspect of responsible sourcing.

Bridging Function and Safety

The capillary thermostat serves as a key example of how precise engineering must align with stringent safety protocols. Its functionality across diverse devices—from a simple kitchen appliance to complex industrial machinery—highlights its importance. For those involved in the capillary thermostat China supply chain, a shared commitment to understanding and meeting these comprehensive safety requirements ensures that these components perform their vital role reliably, forming a dependable link in the manufacture of safe and effective products worldwide.

-

WHD-E-CU Copper Adjustable Capillary Temperature Controller

WHD-E-CU Copper Adjustable Capillary Temperature Controller -

Stainless Steel Adjustable Capillary Temperature Controller

Stainless Steel Adjustable Capillary Temperature ControllerThe stainless steel adjustable capillary thermostat is a mechanical temperature regulating devic...

-

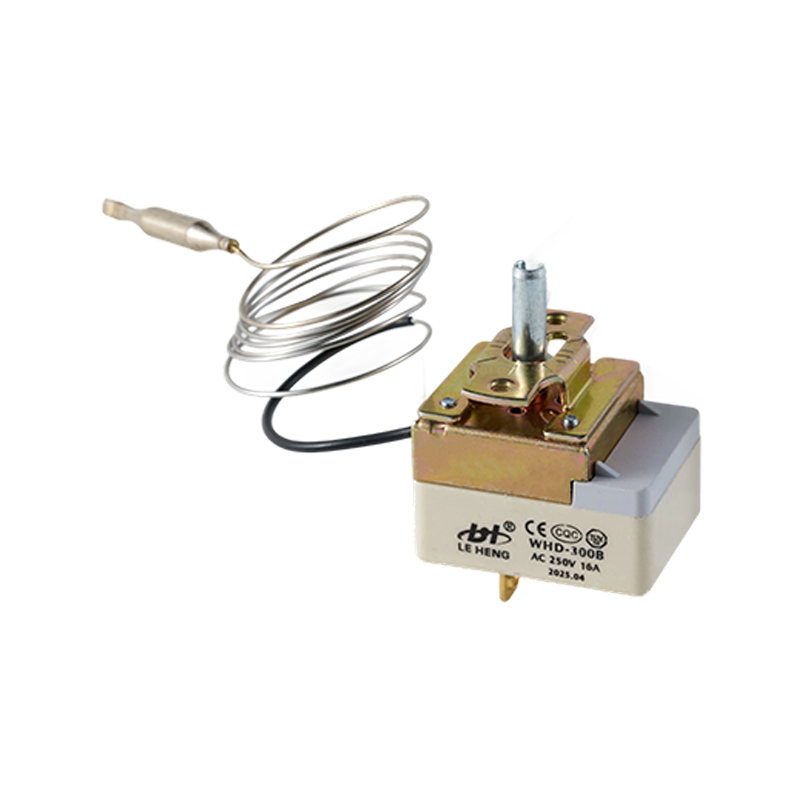

WHD-B(16A/25A) Adjustable Temperature Mechanical Capillary Thermostat

WHD-B(16A/25A) Adjustable Temperature Mechanical Capillary ThermostatWHD-B(16A/25A) Adjustable Temperature Mechanical Capillary Thermostat is specially designed for ...

-

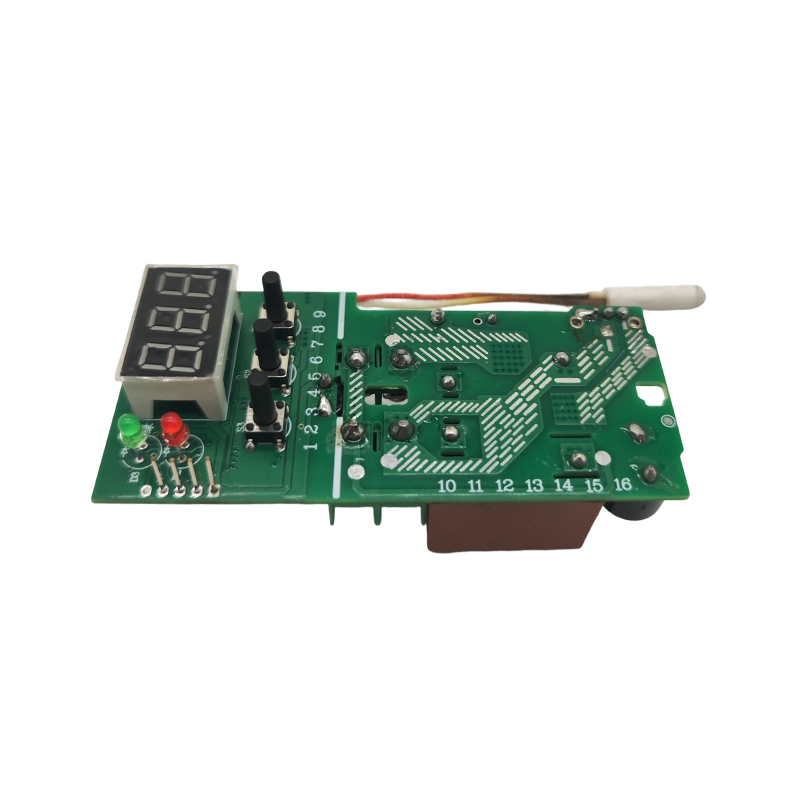

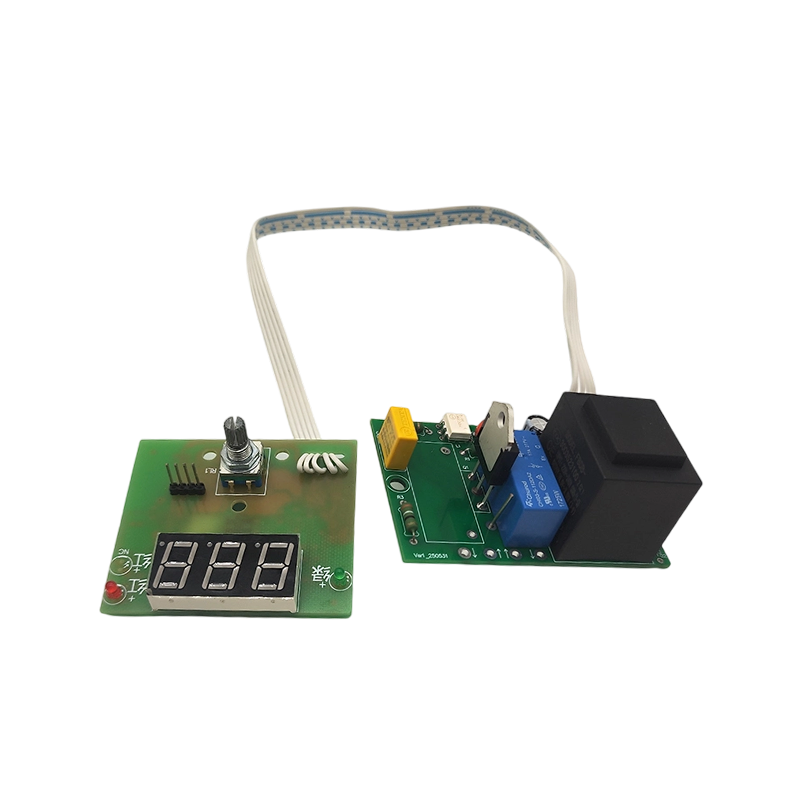

WHD-RQ400-BY Digital Display Thermostatic Controller

WHD-RQ400-BY Digital Display Thermostatic ControllerThe WHD-RQ400-BY digital thermostat is an intelligent control device designed specifically for h...

-

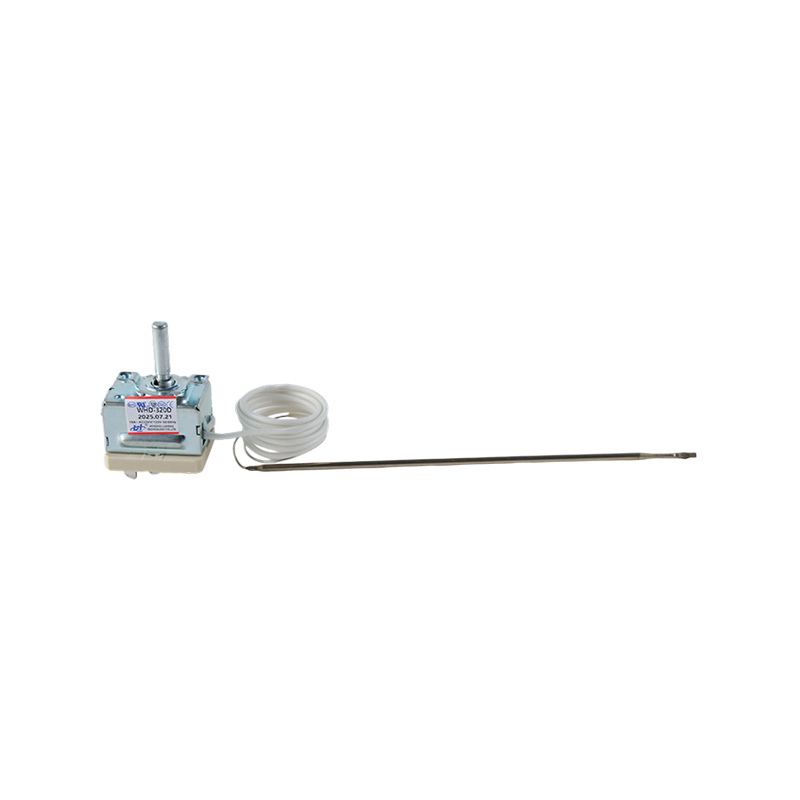

WHD-H2 320 Degree Oven Heating Temperature Limiter

WHD-H2 320 Degree Oven Heating Temperature LimiterThe WHD-H2 oven heating limiter is designed for precise temperature control, with a maximum limi...

-

WHD-D Adjustable Mechanical Temperature Thermostat

WHD-D Adjustable Mechanical Temperature ThermostatThe WHD-D adjustable mechanical thermostat offers reliable temperature control. It features a ma...

-

WHD-YL260 Oil Furnace Digital Thermostat

WHD-YL260 Oil Furnace Digital ThermostatThe WHD-YL260 oil furnace thermostat is an intelligent temperature control device designed speci...

-

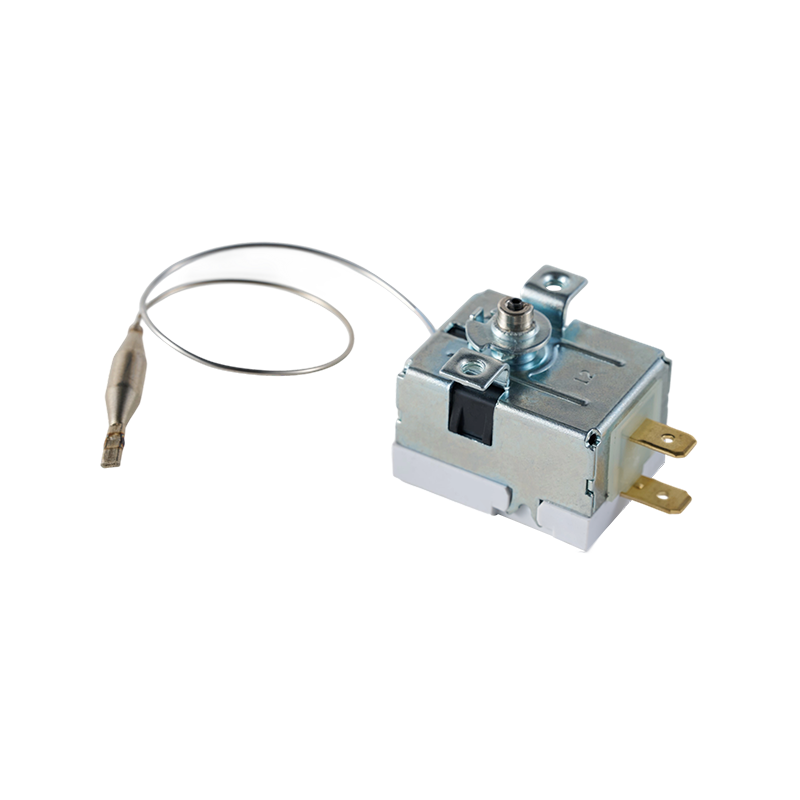

WHD-EM Limit Temperature Controller

WHD-EM Limit Temperature ControllerThe WHD-EM limit temperature controller is a highly reliable device for critical temperature mon...

-

+86-15957748531

+86-15558959105

+86-18583671075

+86-18815077137 -

jilly@wzleh.com

east@wzleh.com

scott@wzleh.com

alan@wzleh.com

- STI Park #B-2, Hongqiao Yueqing City, Zhejiang, China, 325608

English

English Türk

Türk