WHD-E copper adjustable copper capillary thermostat is a mechanical temperature regulating devic...

Refrigerator Thermostat Installation Guide for Diverse Applications

The correct installation of a Refrigerator thermostat is important for ensuring efficient operation and accurate temperature control in any cooling appliance. The process shares core principles whether applied to a home kitchen unit or a commercial walk-in cooler, though the scale and specific requirements differ. This guide outlines the universal steps while highlighting considerations for more demanding environments. For both contexts, the installed component, often a capillary type, is frequently sourced from a broad industrial base, with the sector known as capillary thermostat china representing a substantial source of such components known for adaptable production to various needs.

Core Installation Principles Common to All Units

The foundational steps for installing a capillary tube Refrigerator thermostat are consistent. Safety is the immediate priority: the appliance must be completely disconnected from its power source. The installer must then identify and access the mounting location for the thermostat body, usually inside an interior panel. The capillary tube and its sensing bulb require careful handling to avoid kinks or damage. Their placement is critical; they must be securely fastened in the designated location—often in direct contact with an evaporator coil or in an airstream—to guarantee the thermostat responds accurately to the correct temperature. Electrical connections must be tight and correct according to the wiring diagram. After reassembly, a functional test over 24 hours is recommended to verify that the cooling cycle operates as intended.

Specific Demands in Commercial Refrigeration Environments

Commercial refrigeration systems, such as those in restaurants, supermarkets, or storage facilities, place different demands on a Refrigerator thermostat. These systems often operate for longer hours, experience more frequent door openings, and must maintain strict temperature ranges for food safety. The thermostat must therefore manage a higher number of compressor cycles and withstand greater electrical loads. The sensing element may need to be calibrated for a wider or different temperature range. In these settings, durability and consistent performance under load are key factors in component selection.

Sourcing Components for Varied Requirements

The need for reliable components in both residential and commercial repair or manufacturing has supported a global network of suppliers. The manufacturing capacity associated with the capillary thermostat in China is notable for its ability to accommodate a spectrum of requests. This includes adjustments to capillary tube length, variations in temperature set points, and different electrical contact ratings. This flexibility allows buyers, from individual technicians to procurement departments, to source parts that match specific model requirements or custom applications. The availability of such adaptable components supports the maintenance and production of a wide array of refrigeration equipment worldwide.

Ensuring Long-Term Performance After Installation

A successful installation is measured by long-term performance. Beyond the initial mechanical and electrical steps, choosing a component designed for the application's specific demands is a major factor. Whether for a simple household replacement or a part of a larger commercial service, the installed Refrigerator thermostat should offer predictable operation. Components that come from manufacturing regions with extensive experience, such as those linked to capillary thermostat china, often provide a balance of practicality and function. For installers, verifying that a part has appropriate certifications for its intended market and checking its physical and electrical specifications against the application's needs are standard practices for a reliable outcome.

-

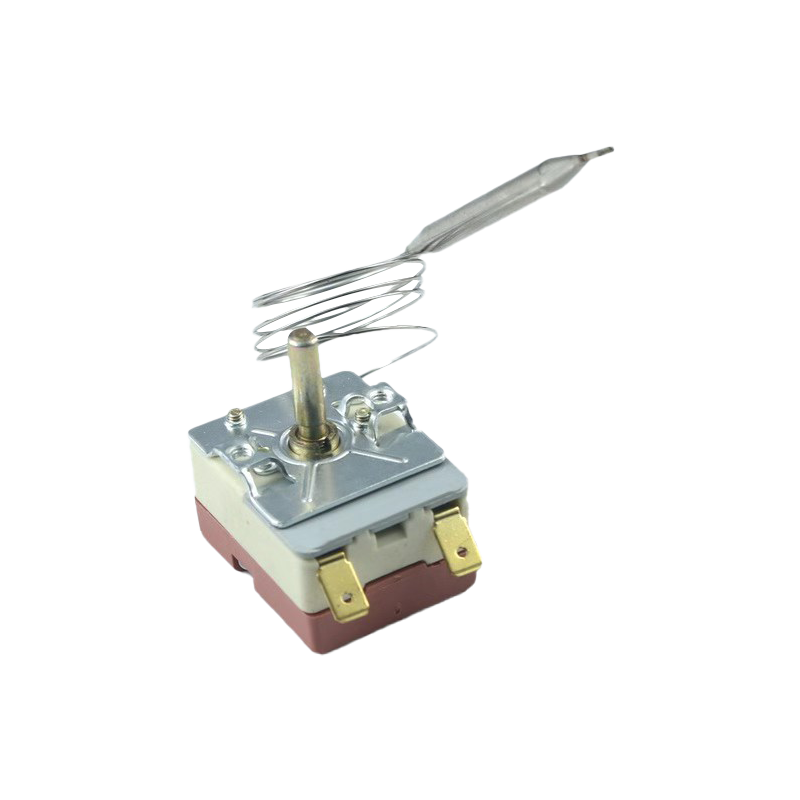

WHD-E-CU Copper Adjustable Capillary Temperature Controller

WHD-E-CU Copper Adjustable Capillary Temperature Controller -

Stainless Steel Adjustable Capillary Temperature Controller

Stainless Steel Adjustable Capillary Temperature ControllerThe stainless steel adjustable capillary thermostat is a mechanical temperature regulating devic...

-

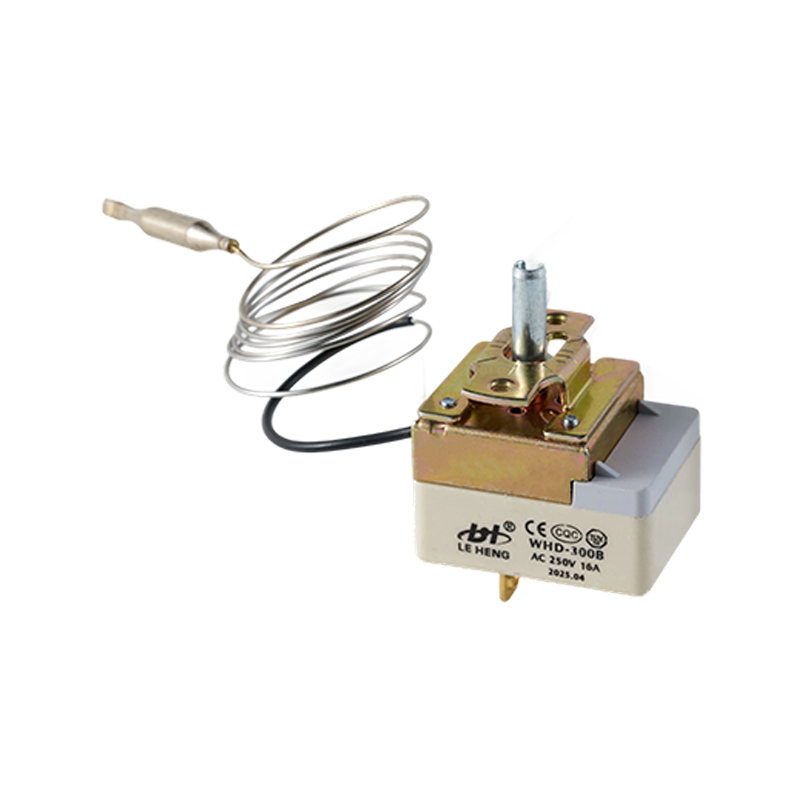

WHD-B(16A/25A) Adjustable Temperature Mechanical Capillary Thermostat

WHD-B(16A/25A) Adjustable Temperature Mechanical Capillary ThermostatWHD-B(16A/25A) Adjustable Temperature Mechanical Capillary Thermostat is specially designed for ...

-

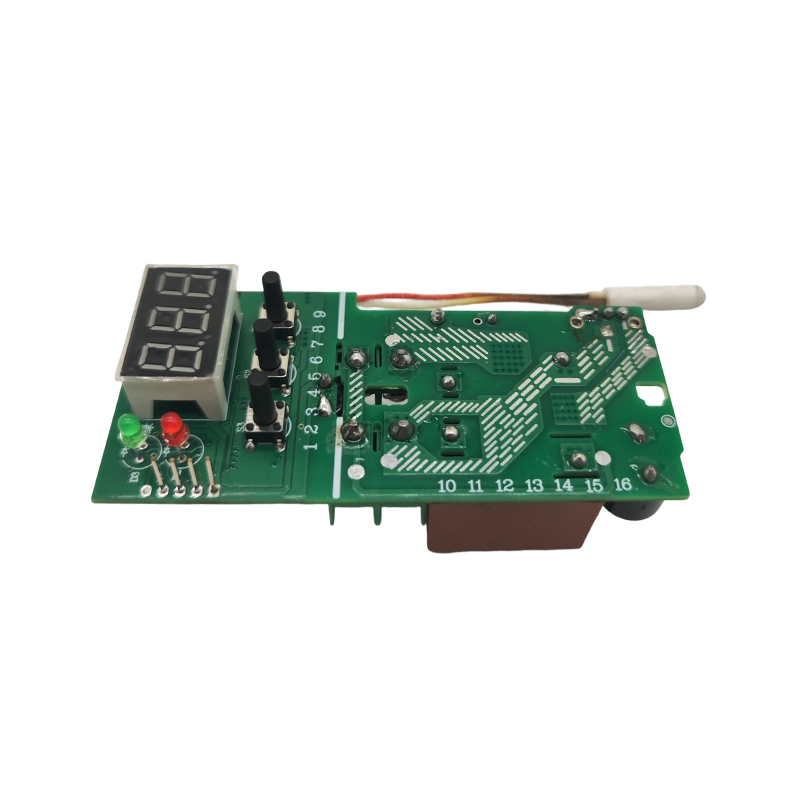

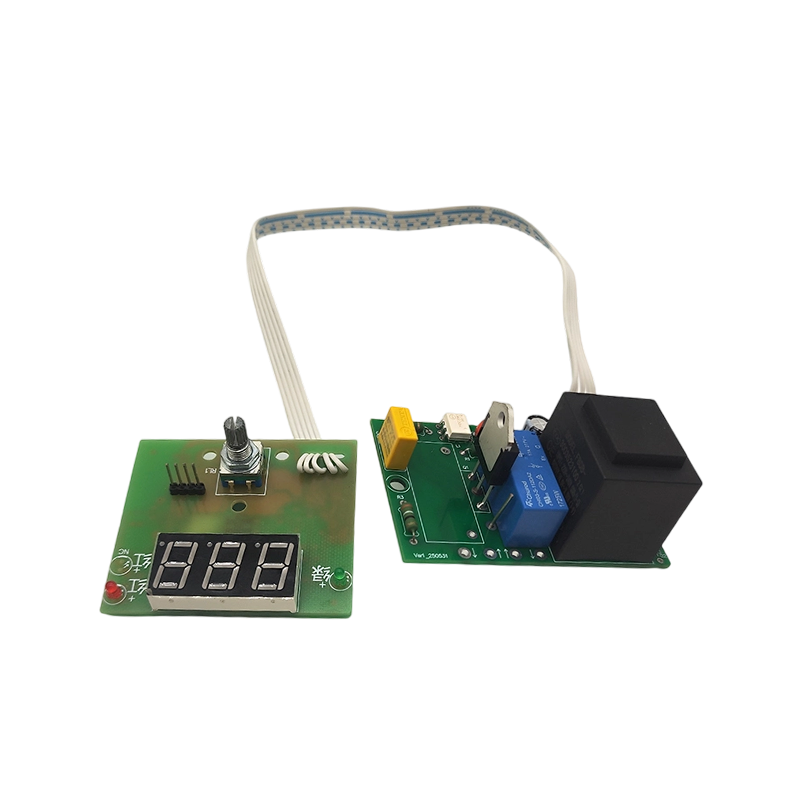

WHD-RQ400-BY Digital Display Thermostatic Controller

WHD-RQ400-BY Digital Display Thermostatic ControllerThe WHD-RQ400-BY digital thermostat is an intelligent control device designed specifically for h...

-

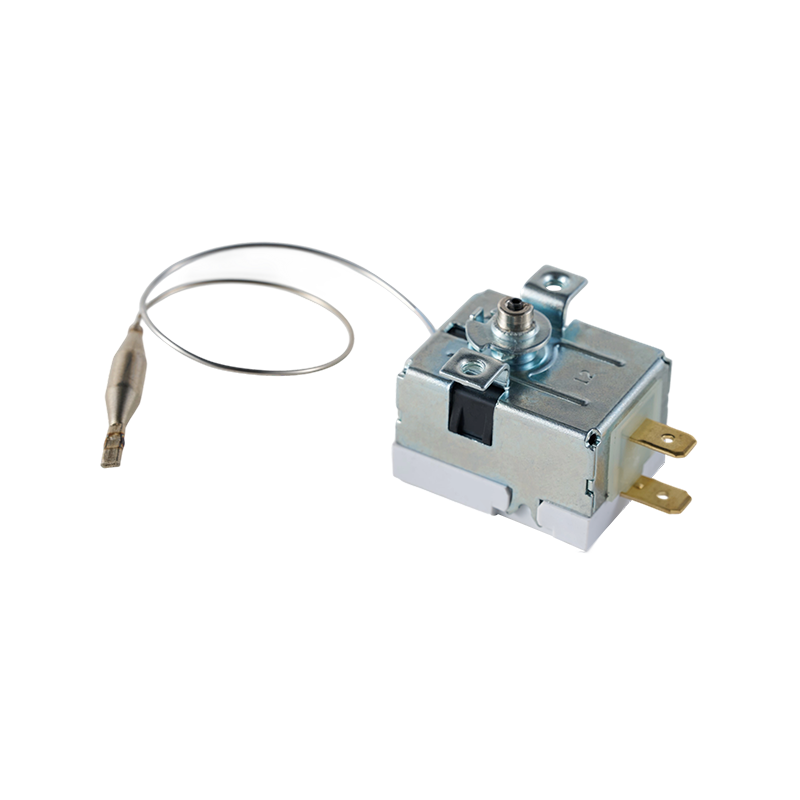

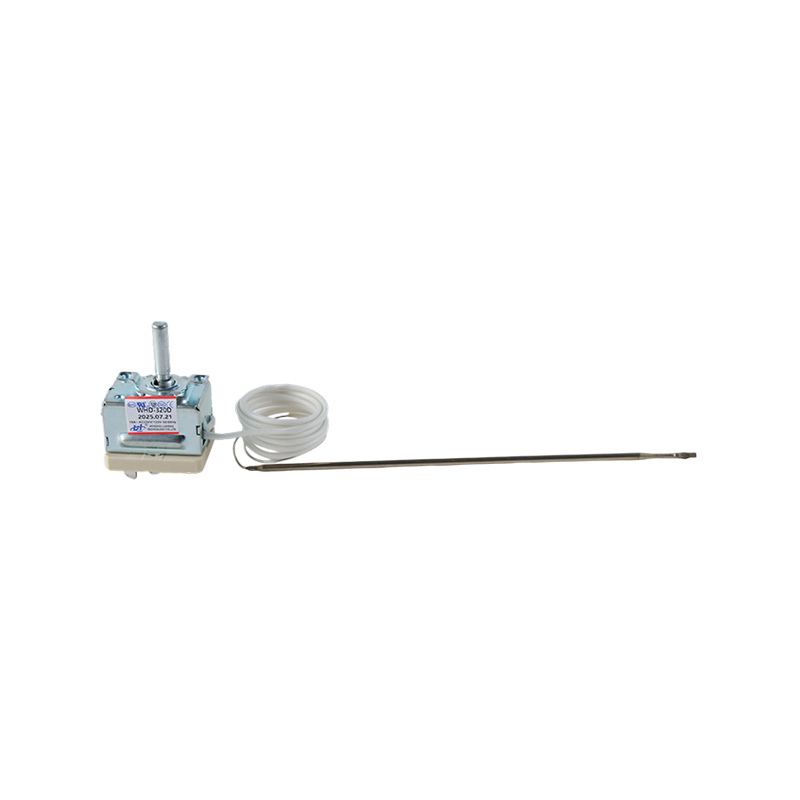

WHD-H2 320 Degree Oven Heating Temperature Limiter

WHD-H2 320 Degree Oven Heating Temperature LimiterThe WHD-H2 oven heating limiter is designed for precise temperature control, with a maximum limi...

-

WHD-D Adjustable Mechanical Temperature Thermostat

WHD-D Adjustable Mechanical Temperature ThermostatThe WHD-D adjustable mechanical thermostat offers reliable temperature control. It features a ma...

-

WHD-YL260 Oil Furnace Digital Thermostat

WHD-YL260 Oil Furnace Digital ThermostatThe WHD-YL260 oil furnace thermostat is an intelligent temperature control device designed speci...

-

WHD-EM Limit Temperature Controller

WHD-EM Limit Temperature ControllerThe WHD-EM limit temperature controller is a highly reliable device for critical temperature mon...

-

+86-15957748531

+86-15558959105

+86-18583671075

+86-18815077137 -

jilly@wzleh.com

east@wzleh.com

scott@wzleh.com

alan@wzleh.com

- STI Park #B-2, Hongqiao Yueqing City, Zhejiang, China, 325608

English

English Türk

Türk