Founded in

-

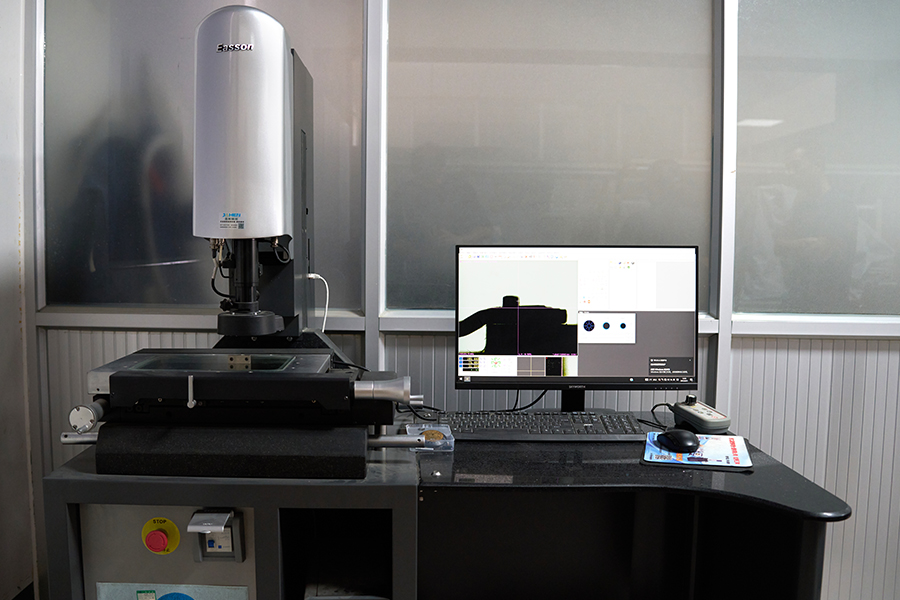

Optical InspectionOur facility is equipped with high-precision optical inspection systems that integrate industrial cameras with automated recognition algorithms to conduct comprehensive surface inspection of products. The system effectively identifies various cosmetic defects including scratches, foreign matter, cracks, blurred printing and assembly misalignment. With its high detection accuracy, this solution is particularly suitable for rapid screening in mass production environments, ensuring consistent product appearance across all batches and full compliance with export quality requirements. The automated inspection process maintains both efficiency and reliability throughout high-volume manufacturing operations.01

-

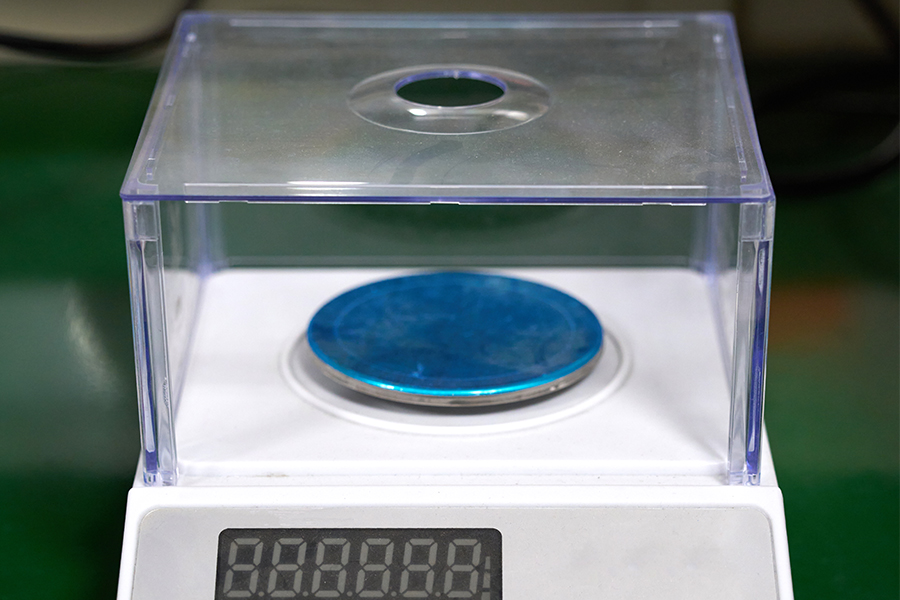

Electrical TestingEach product undergoes complete electrical performance verification prior to shipment, examining critical parameters such as resistance values, voltage, current, continuity, and trigger response times. Our testing process employs calibrated load simulators and digital test stations to validate temperature response characteristics, power supply stability, and contact reliability. This comprehensive verification process helps maintain consistent functional performance and parameter accuracy in field applications, while supporting compliance with industry standards. Our quality control system integrates automated testing procedures throughout the manufacturing process.02

-

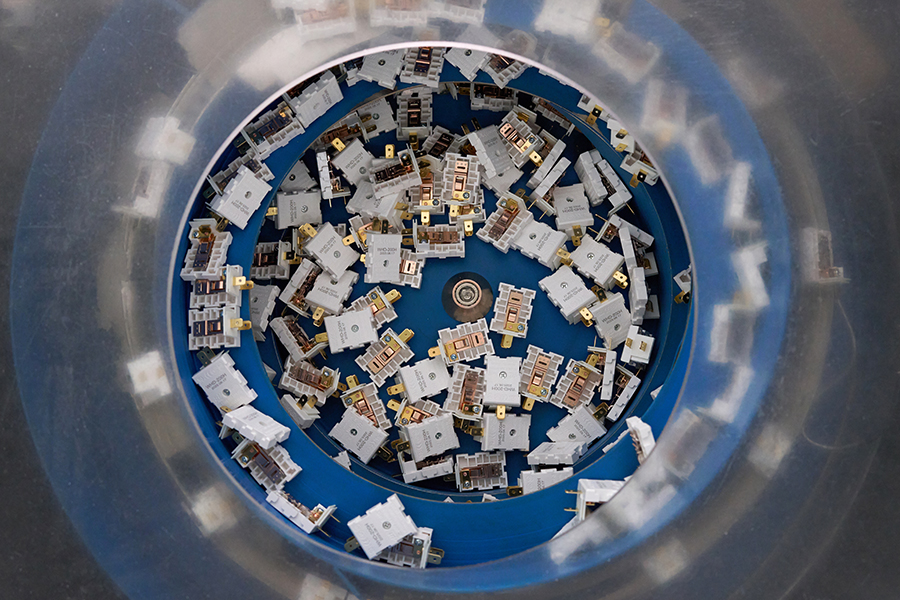

Aging / Reliability TestingTo evaluate product stability under prolonged operation and extreme conditions, we conduct continuous powered testing using specialized equipment including vacuum aging chambers and temperature/humidity environmental chambers. The standard testing protocol spans 24-72 hours, during which we monitor temperature variations, electrical parameters, and failure rates. This process allows for the elimination of early-failure components, supporting the delivery of products with demonstrated durability and performance consistency. Our accelerated life testing methodology follows industry-standard reliability assessment procedures while maintaining appropriate safety margins in test conditions.03

-

Highly automated production lineOur highly automated production line incorporates advanced equipment with intelligent control systems. When non-conforming conditions are detected during manufacturing, the system automatically initiates stoppage protocols to maintain process stability and product consistency. This automated quality intervention system contributes to improved product uniformity and manufacturing efficiency throughout the production cycle.04

English

English Türk

Türk